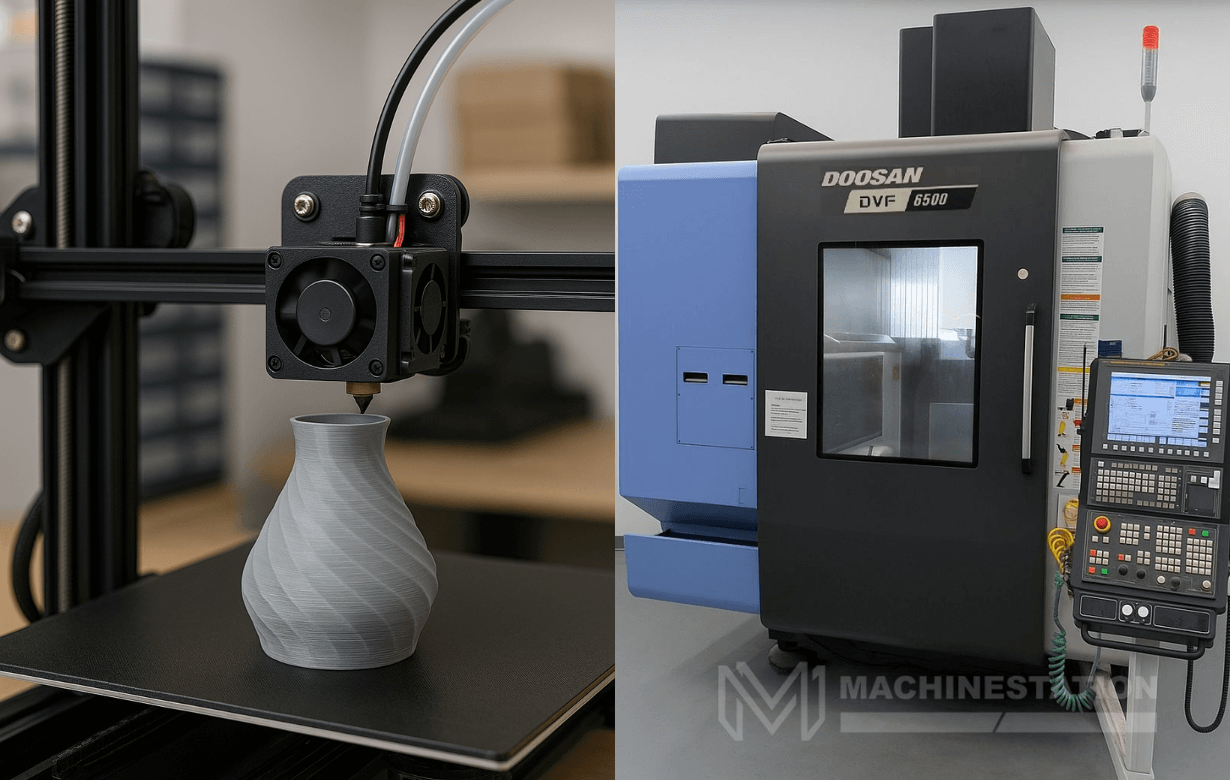

3D Printing vs. CNC Machining: Understand the Differences

The world of manufacturing now has different methods for machining different elements. While CNC machining has been known for decades now, 3D machining has also recently started making some impacts in the manufacturing market. 3D printing uses the method of additive manufacturing in contrast to the subtractive manufacturing methods of CNC machines. Both of these technologies have revolutionized the production, prototyping, and design of various products. But there are several fundamental differences between 3D printing vs CNC machining, and in this blog, we are going to discuss them in detail.