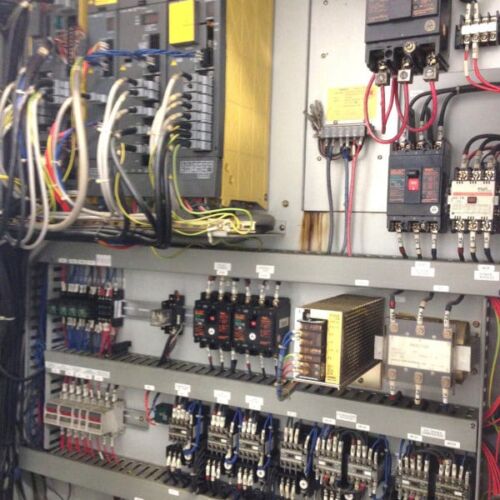

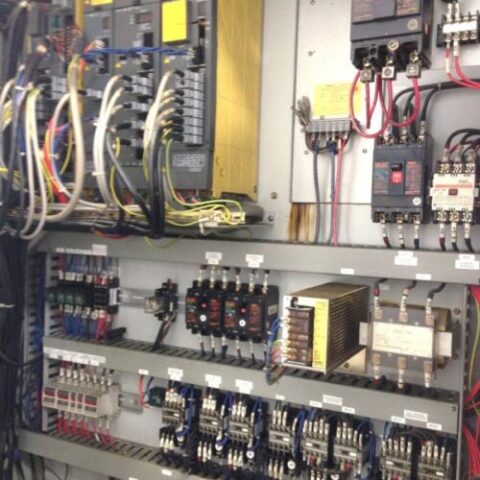

- Fanuc Series 21-M Control.

- RS-232C Port.

- JIS NT #40 (CAT40 / BT40) Spindle Taper.

- 20-Station Automatic Tool Changer.

- Full enclosed chip/splash shield.

- Flood coolant system for cutting.

- Flood coolant system for chip disposal.

- Automatic centralized lubrication system.

- Travels:

- X-Axis: 16.93″

- Y-Axis: 9.84″

- Z-Axis: 13.78″

- Working Dimensions: 15.75″ x 13.78″

- Taper: JIS NT#40 (CAT40 / BT40)

- Speed Command: 1 RPM (directly programmable with 5-digit S code)

- Speeds Range: 200 to 6,000 RPM

- Distance Between Spindle Center to Column: 13.50″

- Distance Between Spindle Nose to Pallet Top: 4.33″ to 18.11″

- Motor (continuous / 30 min.): 5 Horsepower / 7.5 Horsepower

- Cutting Feed Rate (X, Y, Z,): 0.004 to 157 in/min

- Rapid Traverse Rate (X, Y, Z,): 944.88 in/min

- Tool Capacity: 20

- Maximum Tool Diameter: 2.99″

- Maximum Tool Length: 9.65″

- Maximum Tool Weight (single / total): 13.2 lbs. / 176 lbs.

- Machine Weight: 10,000 lbs.

- Electrial: 230 Volt, Three Phase

- Overall Dimensions: 100″ x 84″ x 84″ tall

MACHINE USE AND SAFETY: Buyer acknowledges that the goods described herein are pre-owned used goods which were neither designed or manufactured by the Seller, nor has the Seller knowledge of, or control over, the prior use or misuse of said goods: nor does the Seller have knowledge or control over the application of these goods by the Buyer. It is the Buyer’s (user’s), responsibility to provide proper safety devices, equipment and instructions for any particular use, and to take all necessary steps to confirm to all Federal, State or Local Government Safety Standards and including OSHA.

BUYER IS RESPONSIBLE FOR SCHEDULING TRANSPORTATION OF THIS MACHINE, AS WELL AS ALL COST TO MOVE IT. IF YOU NEED HELP WITH SCHEDULING, PLEASE CONTACT US AND WE WILL ASSIST YOU. WE SHIP GLOBALLY.