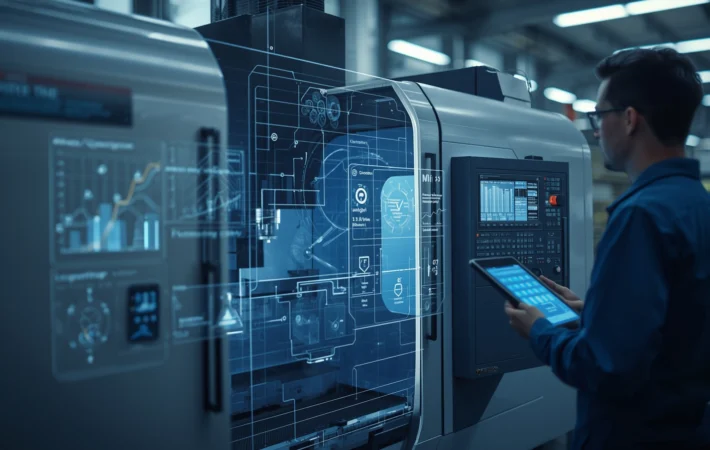

Used CNC Machine Inspection Checklist: What to Look for Before You Buy Used CNC Machines

Buying used CNC machines is a financially sound step for your business. You get to buy machines at a lower cost for your business, with similar features to a new one. But buying used CNC machines also needs a bit of effort. There are several machines available in the market of different brands, but you need to choose the right one for yourself. From the features of the machine to the current condition and hours of operation, everything needs to be deeply inspected before you buy a machine. Now, if you want to get a detailed list of what are the things you need to look for while buying a used CNC machine, then read till the end and your doubts will be cleared.