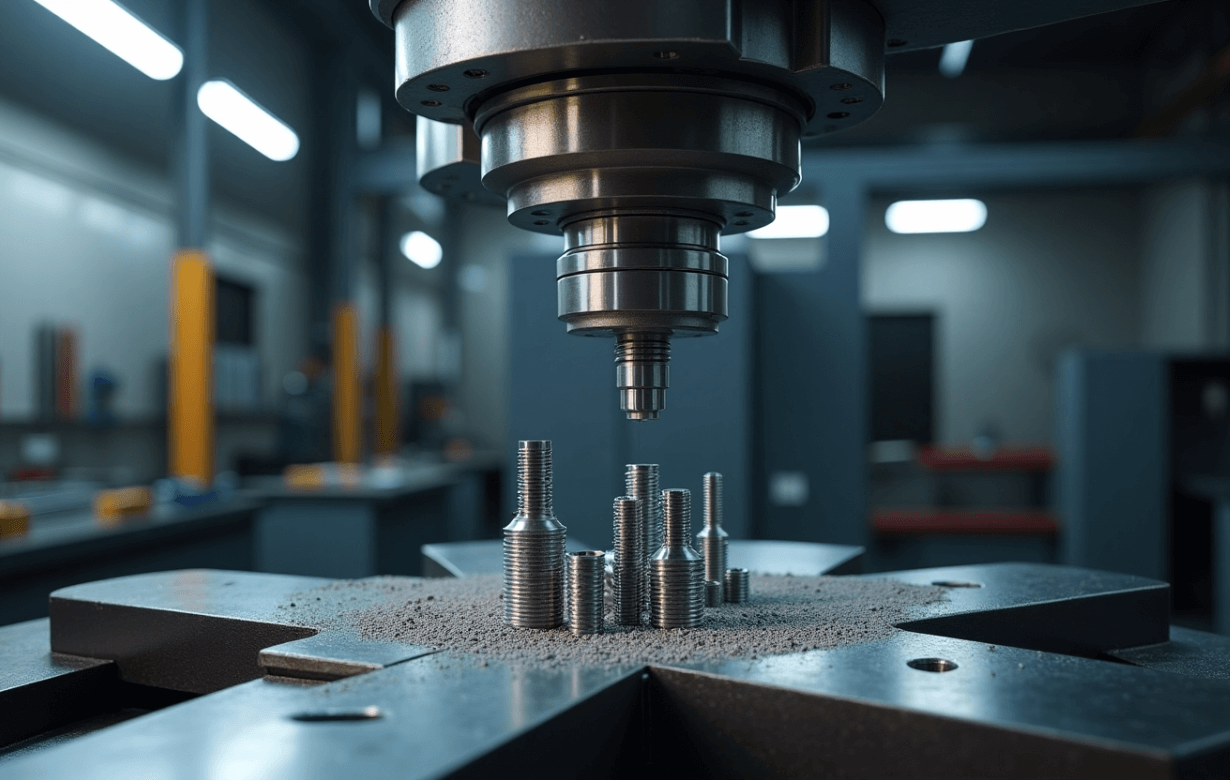

CNC Machine for Bolts

Bolts are one of the most fundamental parts of several manufacturing businesses all around the world, which range from aerospace and defence to electronics and wooden products. But today, we will discuss which CNC machine you can use to manufacture bolts. In one line, the answer is CNC lathe, as they’re a right fit to make products that have cylindrical or circular shapes. Let’s discuss in detail why the CNC lathe is the right fit for machining bolts and how to do that.