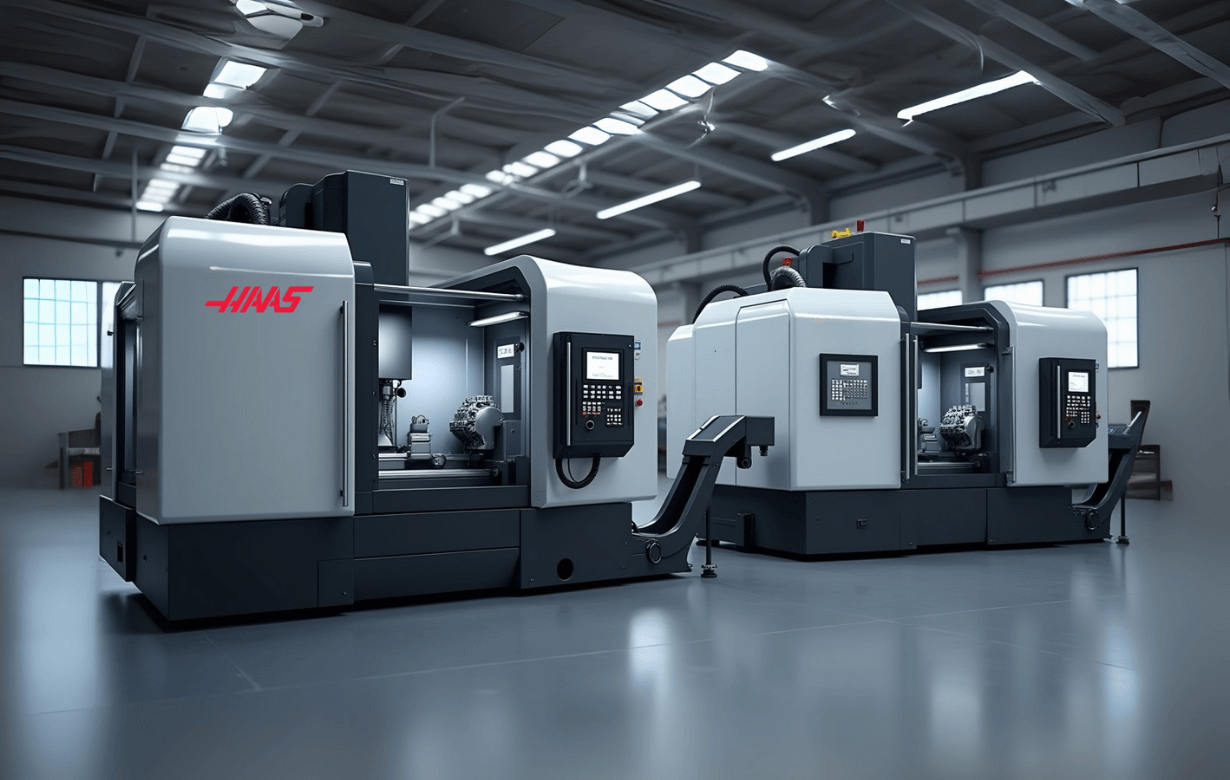

Haas CNC machines VS Other Major Brands: Which is Best?

When you start planning to buy a CNC machine, you are destined to get bombarded with different CNC brand names, and a lot of them are really good brands like Haas, Mazak, DMG Mori, Okuma, and Doosan. But if you are not planning to buy one machine from all, then what should you do? Then you will have to analyse and find out which brand is the best choice for you. All the brands come with their strengths and weaknesses, so it becomes our responsibility to help you understand which brand can be best suited for your machining shop or manufacturing business. In this blog, we will discuss the advantages that Haas has over its competitors and which group of customers should go with a Haas CNC machine over the other.