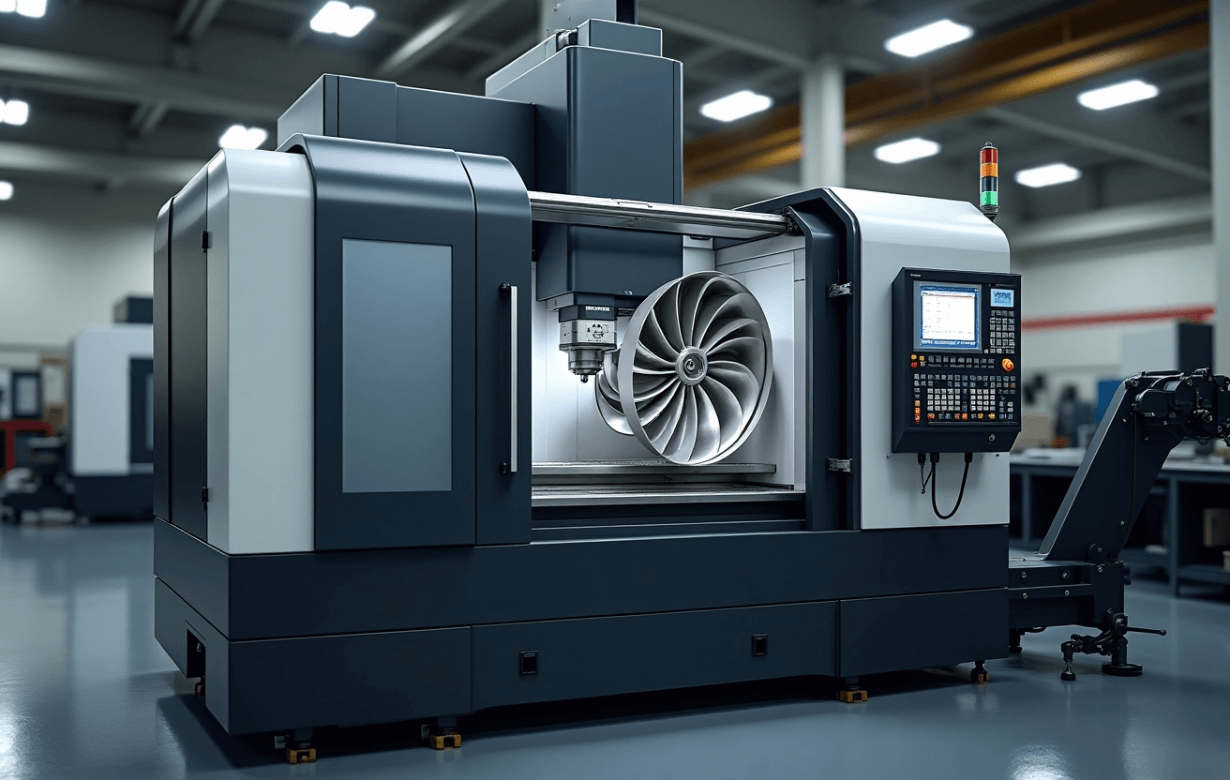

CNC Machine for Turbine Blades

Turbine blades are a complex design part that is also an integral part of an airplane and requires precise machining work for better accuracy. So, which CNC machine is needed for manufacturing those turbine blades? The direct answer is 5-axis CNC machines. This type of CNC machine provides versatility, precision, and the capability to handle intricate geometries. A 5-axis CNC machine enables the simultaneous movement of all five axes, allowing for the approach of the workpiece from different angles.