Key Benefits of the Haas ST-40 for Precision Turning and Heavy-Duty Work

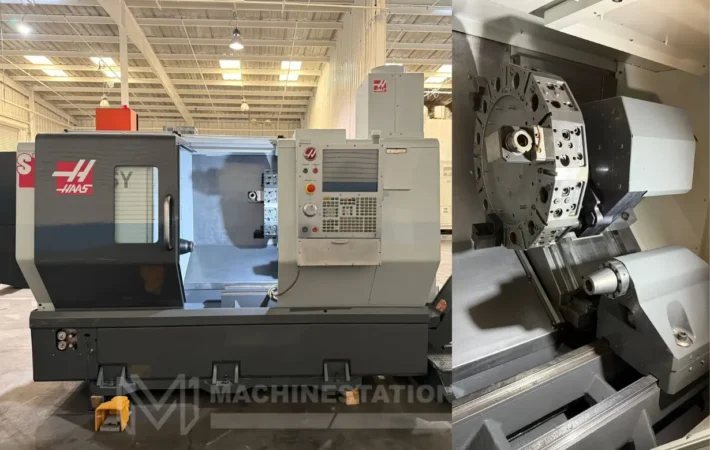

Haas ST series is a lineup of different high quality CNC turning center machines that have versatile features making them suitable for different kinds of machining shops. Among different machines of the ST series of Haas, the ST-40 has been a machine that is often appreciated by several machinists for different reasons, and the machine has turned out to be a favorite for manufacturing shops during heavy duty manufacturing work.

Different Haas ST-40 specifications have made this machine the right choice for precision and heavy duty turning works. So, in this blog, we will discuss the top Haas ST-40 benefits that have made this machine a favorite of several manufacturers.