Description

| CINCINNATI MONOSET TOOL & CUTTER GRINDER | |

|---|---|

| Make | The Cincinnati Milling Machine Co. |

| Model No. | Monoset MT |

| Country of Origin: | USA |

| Serial # | 2D1C5T-10 |

| Condition | Very Good |

- CINCINNATI MONOSET Features:

- The Cincinnati Monoset Tool & Cutter Grinder is particularly useful for quickly preparing special cutters when needed.

- While the Monoset may be used for conventional resharpening, its many built-in features eliminate the need for special attachments and make it particularly adaptable to the production of difficult “trick” or “problem” cutters and the reclamation or slvaging of worn-out cutters. All types of cutters within the range of the machine–end mills, reamers, counterbores, form cutter, etc., having straigh, tapered or spiral teeth, and involving convex or concave radii–can usually be resharpened, or even ground from the solid if necessary without the need for special attachments.

- As the name “MONOSET” implies, all operations necessary in the production of most types of cutters can generally be performed with a single setting or chucking of the workiece. This assures excellent concentricity and provides smooth cutting qualities by having all teeth carry and equal share of the cut.

- A few of the outstanding features which combine to give the Monoset Grinder its unusual degree of flexibility and versatility are:

- -Automatic generation of infinitely variable spiral leads.

- -Workhead swivel mount for generating accurate radii.

- -Micrometer dials and stops for all slides.

- -Simple, accurate indexing devices.

- -Wheelhead adjustable in three planes.

- -Workhead motor drive for cylindrical grinding.

- Workhead mounted on a large, smooth action turntable base permits swiveling the workhead through 235 degrees in a horizontal plane.

- Offset slide for workhead spindle permits centerline of spindle to be offset from center of turntable for generation of convex or concave radii on workpiece.

- Built-In spiral lead mechanism generates straight or tapered right-hand or left-hand, infinitely variable spirals with a single simple adjustment; no change gears required.

- Simple, easy action indexing mechanism simplifies set-ups and indexings from tooth to tooth.

- One-Shot lubrication systems for both wheelhead and workhead units provides efficient, simplified lubrication for all points except workhead and wheelhead spidles.

- The wheelhead unit is carried on three sliding members, permitting longitudinal, transverse, or vertical adjustment. Wheel may be adjusted toward the work, or the work toward the wheel, whichever is more convenient.

- All slides equipped with graduated dials or adjustable micrometer stops greatly simplifies accurate positioning of the sliding elements.

- All controls conveniently grouped within easy reach of the operator reduces operator fatigue.

- All operating mechanisms are fully enclosed to prevent entrance of dirt or grit. Helps reduce maintenance and increase the useful life of the machine.

- Convenient, easily read clearnace angle scales, graduated in degrees, on both vertical and transverse wheelhead slides simplifies the selection of clearance or “back-off” angles.

- Workhead main slide may be operated from either front or left end. Operator may select the control most convenient for him.

- Motor drive for workhead spindle for form and cylindrical grinding.

- Built-In tool compartment in base. An added convenience in keeping tools, collets, wheels, etc., within arm’s reach of working position.

- CINCINNATI MONOSET Specifications:

- Capacities:

- Swing Over Main Slide: 12″

- Maximum Distance Between Spindle Nose and Tail Center: 6″

- Maximum Wheel Diameter (6,000 ft. per minute, approx.): 3-1/2″

- Collet Work Diameter (minimum / maximum): 1/8″ / 1-1/4″

- Range:

- Longitudinal Movement of Main Slide: 5-3/4″

- Offset Slide Movement (either side of center): 2-1/4″

- Vertical Slide Travel of wheelhead Above Center: 4-1/4″

- Vertical Slide Travel of wheelhead Below Center: 4-1/2″

- Transverse Slide Travel of Wheelhead: 7-1/2″

- Longitudinal Slide Travel of Wheelhead: 6″

- Angular Range of Workhead in Horizontal Plane (workhead swivel base): 235 degrees

- Angular Range of Workhead in Vertical Plane (workhead angulard adjustment), above or below centerline position: 40 degrees

- Speeds:

- Grinding Wheel Spindle (two speeds): 6,000 & 8,000 RPM

- Workhead Spindle: 287 RPM

- General:

- Wheelhead Motor: 1/3 Horsepower, 208-220 / 440 Volt, 3,450 / 2,850 RPM, 1.4 / 0.7 Amps, 60 / 50 Hz

- Electrical: 208 Volt, Three Phase, 60 Hz

- Overall Dimensions: 54″ x 36″ x 58″ tall

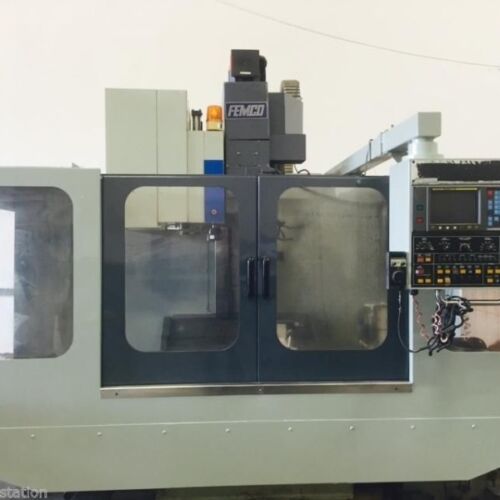

CINCINNATI MONOSET Comes as shown in pictures.

GUARANTEE: If any machine guaranteed by us does not prove satisfactory mechanically, the Purchaser may return it freight prepaid within 14 days from date of shipment and we will refund the purchase price in full. This does not apply to machine sold “as is” or “subject to inspection”. This guarantee applies only to machines which we own. The machine must be returned in the same condition that it left our warehouse. MachineStation shall not be responsible for any damage done by truckers, riggers, or other parties. Machine damaged in shipping are not covered under the return privilege.

WARRANTY: Seller makes no warranties of any kind whatever, expressed, or implied. All specifications and descriptions of said goods are approximate, not binding and meant only as a guide. It is the Buyer’s responsibility to inspect the goods and ascertain if the specifications, description and condition of the goods confirm to the Buyer’s requirement.

MACHINE USE AND SAFETY: Buyer acknowledges that the goods described herein are pre-owned used goods which were neither designed or manufactured by the Seller, nor has the Seller knowledge of, or control over, the prior use or misuse of said goods: nor does the Seller have knowledge or control over the application of these goods by the Buyer. It is the Buyer’s (user’s), responsibility to provide proper safety devices, equipment and instructions for any particular use, and to take all necessary steps to confirm to all Federal, State or Local Government Safety Standards and including OSHA.

BUYER IS RESPONSIBLE FOR SCHEDULING TRANSPORTATION OF THIS MACHINE, AS WELL AS ALL COST TO MOVE IT. IF YOU NEED HELP WITH SCHEDULING, PLEASE CONTACT US AND WE WILL ASSIST YOU. WE SHIP GLOBALLY.