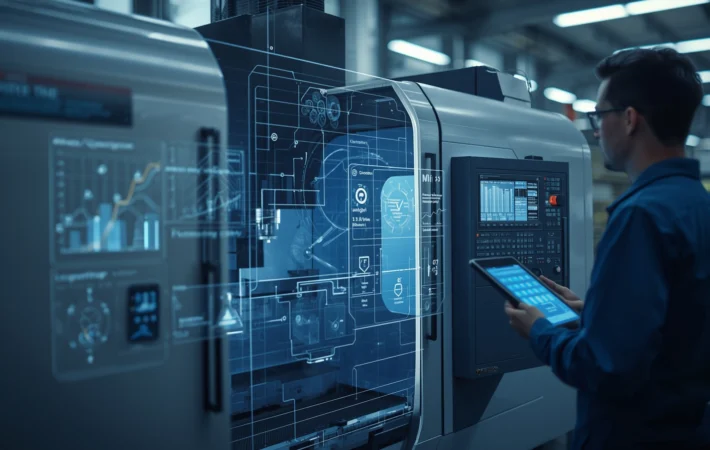

How Manufacturers Use the Mazak Nexus Series to Scale Production?

When you are looking for a CNC machine that can help you scale your production up, then the Mazak Nexus is one of the most popular names that you are definitely going to encounter. These machines have a great capability of doing different kinds of machining work. These machines are also often appreciated for their manufacturing capabilities by manufacturers across the world. But how do manufacturers use Mazak Nexus CNC machines for scaling production? If that is your question, then read this blog till the end to get the answer.