*All specifications are approximations and are subject to verification. Comes as shown in the images. Please call us if you have any questions before making a purchase. All sales are final.*

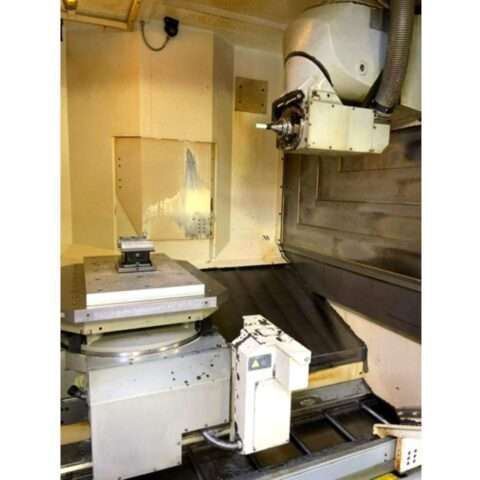

| Make: | Deckel Maho |

| Model: | DMF 360 LINEAR |

| Year: | 2008 |

| Condition: | Used |

| Machine Type: |

|---|

- CNC Vertical Machining Center

- Thermo-Symmetrical Traveling Column Design (2nd Generation)

- Linear Drive X-Axis

- 4th Axis Equipped / 5-Axis Capable

- Mineral Cast Machine Bed for Vibration Damping

|

| Travels & Accuracy: |

|---|

- X-Axis Travel: 141.7″

- Y-Axis Travel: 43.3″

- Z-Axis Travel: 35.4″

- Positioning Accuracy (X): 0.0005″

- Positioning Accuracy (Y/Z): 0.0004″

- Direct Linear Measuring Systems on All Axes

|

| Feedrates & Dynamics: |

|---|

- Rapid Traverse X-Axis: 1,575 IPM (Optional 3,150 IPM)

- Rapid Traverse Y/Z-Axis: 1,575 IPM (Optional 2,362 IPM)

- Max Cutting Feedrate: 3,150 IPM

- Feed Force (X/Y/Z): 2,698 / 2,248 / 2,698 lbs

- Position Resolution: 0.00004″

- Chip-to-Chip Time: < 6 sec (Optional Dynamics Package)

|

| Spindle: |

|---|

- Standard Spindle Speed: 8,000 RPM

- Standard Spindle Power: 31.5 HP (100%)

- Tool Interface: SK40

- Optional Spindles:

- 14,000 RPM – SK40 / HSK-A63

- 18,000 RPM – SK40 / HSK-A63

- 10,000 RPM Heavy-Duty – SK50 / HSK-A100

- Optional Spindle Power: 59.0 HP (40%)

|

| Automatic Tool Changer: |

|---|

- Standard Tool Capacity: 30 Tools

- Optional Tool Capacity: 60 or 120 Tools

- Max Tool Weight: 13.2 lbs (Optional 26.5 lbs)

- Max Tool Diameter: 3.1″ (4.5″ Adjacent Pocket Empty)

- Max Tool Length: 11.8″ (Optional 14.2″)

- Traveling Tool Magazine for Reduced Chip-to-Chip Time

|

| Table & Workpiece Capacity: |

|---|

- Table Size: 165.4″ × 43.3″

- Max Table Load: 11,023 lbs

- Optional NC Rotary Table Diameter: 41.3″

- Rotary Table Load Capacity: 2,646 lbs

- B-Axis Swivel Head: ±100°

|

| 5-Axis & Mill-Turn Capability: |

|---|

- 5-Axis Simultaneous Machining via B- and C-Axis

- Mill-Turn (FD) Table Option

- Turning Speed up to 1,000 RPM

- Twin-Table Machining with Partition Wall (Optional)

|

| CNC Control: |

|---|

- DMG ERGOline® CNC Control

- 19″ Widescreen Display

- 3D Workpiece Simulation

- DMG SOFTkeys® & SMARTkey® User Access

- Control Options:

- Siemens 840D Solutionline Operate (ShopMill Open)

- Heidenhain iTNC 530 with smarT.NC

|

| Accuracy, Monitoring & Automation: |

|---|

- 3D quickSET® Axis Calibration

- Collision Monitoring (Standard with 5-Axis)

- Tool Measurement: Blum Laser / TT140

- Workpiece Probing: TS649 / PP60

|

| Coolant & Chip Management (Options): |

|---|

- Through-Spindle Coolant: 580 PSI / 1,160 PSI

- Air Blast Through Spindle

- Minimal Quantity Lubrication (MQL)

- Chip Conveyor

- Rotating Safety Glass

|

| Key Highlights: |

|---|

- 141.7″ Long X-Axis Travel for Large Components

- Linear Drive X-Axis for High Precision & Speed

- Heavy-Duty Spindle Options up to SK50 / HSK-A100

- Full 5-Axis & Mill-Turn Capability

- Ideal for Aerospace, Mold & Die, Rail & Automotive Applications

|