Description

| Burgmaster 2A Automatic Indexing Turret Drill Press | |

|---|---|

| Make | Burg Tool Manufacturing Co. |

| Model No. | 2A |

| Country of Origin: | USA |

| Serial # | 2555 |

| Condition | Very Good |

- Burgmaster 2A Features:

- The 2A Burgmaster is a precision production machine, with sensitivity and accuracy built-in for high quality work, but rugged, rigid and powerful enough to handle rough work such as castings and forgings.

- Power Indexing Turret Head performs up to six operations on a part before it is moved to another machine, with resultant savings in handling, increase in production, and improved quality of product.

- On the right side of the 2A Burgmaster, within easy reach of the Operator and mounted to the transmission is the Speed Control Drum. Each Spindle has a corresponding 4 position Speed Control Knob which regulates the 2 speed motor and 2 speed Electric Clutches through 4 speeds. Each spindle has a definite gear ratio, with 3 different ratios standard per Turret Head. These coupled with 4 speed transmission, give a preselective range of 12 Spindle Speeds. The Control Drum indexes when Turret indexes.

- Each position of the Turret Head is provided with a rigid Precision Ground Spindle, mounted in preloaded, Double Ball Bearings. Spindle Nose has a 3/4″-16 TPI Male Thread for mounting tools, making for quick interchangeablity of chucks, Morse Taper Sleeves, Tapping Heads, etc. Each Spindle is driven through helical gears by individual clutches, mounted in extra capacity bearings. Only spindle in operating position is revolving. Gears and Bearings of spindle in operating position are lubricated by a gravity feed oil bath.

- Positive Accurate Indexing through a Geneva Crank and Star Wheel plus final location of Turret Head with a springloaded tapered Locating Pin, guarantees fool-proof indexing and very accurate relationship from one spindle to another. A safety clutch (spring loaded) provides protection to index mechanism, spindles, and tools should something interfere with normal index of Turret Head, Speed Control Drum, or Depth Stops. Index is actuated only when Slide is returned to the uppermost position, by a Cam Shaft driven by a Worm Gear, which in turn is driven from the Driving Clutch Shaft Worm. All Gears and Shafts are alloy steel, hardened and ground.

- Accurate Rigid Depth Control – Close tolerances on depth are easily set for each spindle by the rigidly mounted direct reading Micrometer Depth Stop Units. Preliminary adjustment is secured by moving Stop Units in 1″ increments in Dovetail Ways. The Stop Units are then keyed in position and final adjustment is made through direct reading Micrometer Screw and Nut. Stop Screw registers against a hardened Pin inserted into the Rigid Stop Bar. The Stop Bar is mounted to the front of themachine Column and all depth adjustments are made from the front of the machine.

- 8″ Spindle Travel – Perform deep hole drilling or boring, with spindle travel to spare.

- Preselective Spindle Speeds – Wide range of Spindle Speeds, preselective for each spindle, assures proper surface speed for each tool, longer tool life, faster production and betting finish.

- Precision Depth Control – Ridig Depth Stop Assembly permits machining to depth of .002″ or less, consistently.

- Hand Feed – Hand scraping of Dovetail Ways and counterweighting of Slide-Turret Unit assure sensitivity for small diameter tools, and large diameter feed wheel provides necessary leverage to feed large drills with minimum effort.

- Power Turret Index – Change quickly from one tool to the next.

- Precision Table – Has “T” Slots and Coolant Trough. 33″ x 17″ surface ground work surface, with hand scraped Dovetail Ways assure very close alignment of table to spindles.

- Quick Set-Up – Simple control for Spindle Speed and Depth Selection within easy reach of the operator, long spindle travel, and large work area, assure quick changeover from one job to the next, and make the 2A Burgmaster ideal for machining very short and intermediate quantities of parts.

- Will Machine to Very Close Tolerances – Hand scraping of all sliding surfaces, surface ground table, Precision Double Ball Bearings on rigid Spindles, Unit Bored Turret Speeds, assure close concentricity on all operations, plus low micro-inch finishes, and threads, grooves, bores, faces, and diameters to close tolerances.

- Low Maintenances Cost – Rugged precision constructoin, alloy steel gears and shafts (heat treated when necessary), extra capacity bearings, built-in lubrication, with all assemblies simple to get at for service, mean low maintenace cost to you.

- Built-In Coolant System.

- Burgmaster 2A Specifications:

- Table:

- Surface Area: 33″ x 17″

- Slots: 2 @ 9-1/2″ centers x 39/64″

- Adjustment Travel: 10″ approx.

- Turret Head:

- Throat: 12-1/4″

- Mount: 3/4″-16 TPI

- Number of Stations: 6

- Travel: 8″

- Speeds: (spindle 1 & 4) 500-1,000-1,500-3,000 RPM / (spindle 2 & 5) 350-700-1,000-2,000 RPM / (spindle 3 & 6) 225-450-650-1,300 RPM

- Maximum Distance from Spindle to Table: 21″

- Maximum Distance from Spindle to Base: 43″

- Motor: 2 / 1 Horsepower, 440 Volt, 900 / 1,800 RPM, 2.8 / 3 Amps, 60 H

- zGeneral:

- Electrical: 440 Volt, Three Phase, 60 Hz

- Overall Dimensions: 38″ x 50″ x 76″ tall

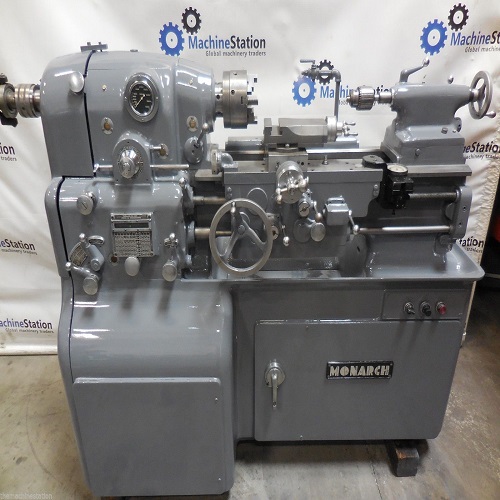

Burgmaster 2A Comes as shown in pictures.

GUARANTEE: If any machine guaranteed by us does not prove satisfactory mechanically, the Purchaser may return it freight prepaid within 14 days from date of shipment and we will refund the purchase price in full. This does not apply to machine sold “as is” or “subject to inspection”. This guarantee applies only to machines which we own. The machine must be returned in the same condition that it left our warehouse. MachineStation shall not be responsible for any damage done by truckers, riggers, or other parties. Machine damaged in shipping are not covered under the return privilege.

WARRANTY: Seller makes no warranties of any kind whatever, expressed, or implied. All specifications and descriptions of said goods are approximate, not binding and meant only as a guide. It is the Buyer’s responsibility to inspect the goods and ascertain if the specifications, description and condition of the goods confirm to the Buyer’s requirement.

MACHINE USE AND SAFETY: Buyer acknowledges that the goods described herein are pre-owned used goods which were neither designed or manufactured by the Seller, nor has the Seller knowledge of, or control over, the prior use or misuse of said goods: nor does the Seller have knowledge or control over the application of these goods by the Buyer. It is the Buyer’s (user’s), responsibility to provide proper safety devices, equipment and instructions for any particular use, and to take all necessary steps to confirm to all Federal, State or Local Government Safety Standards and including OSHA.

BUYER IS RESPONSIBLE FOR SCHEDULING TRANSPORTATION OF THIS MACHINE, AS WELL AS ALL COST TO MOVE IT. IF YOU NEED HELP WITH SCHEDULING, PLEASE CONTACT US AND WE WILL ASSIST YOU. WE SHIP GLOBALLY.