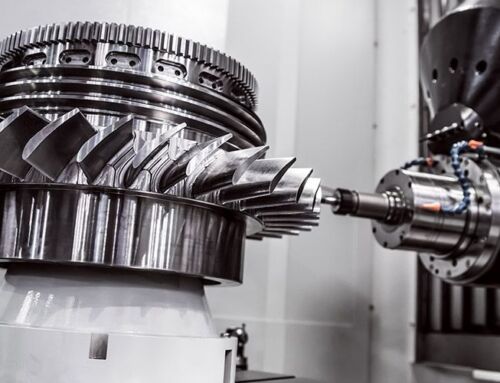

Are you looking for a precision machine that can be used to craft complex shapes and surfaces on any material? If so, then investing in a Multi-Axis Machining Center might just be the perfect fit for your business. Whether you’re a first-time buyer of CNC machinery or an experienced one who wants to upgrade their equipment, we are here to help. We will explain why buying such a sophisticated tool pays off – from the great accuracy of machined parts and its scalability through multiple projects at once, all the way up to more cost effectiveness than manual machines. So if you want to learn more about why getting a Multi-Axis Machining Center is worth it; read ahead!

Advantages of Multi-Axis Machining

A Multi-Axis Machining Center is an incredibly versatile tool for industrial and manufacturing purposes. With its automated systems that can rotate multiple axes it is a powerful asset for creating highly complex shapes and surfaces with great accuracy and precision. Not only that, but this machining center can work on a variety of materials, from plastics to metals; making it a suitable tool for almost any product or construction needs. Furthermore, when compared with other traditional machining processes, it is also very cost-effective. All these advantages make the Multi-Axis Machining Center an essential tool in the world of industrial technology today.

It offers the ability to maneuver along multiple axes with great accuracy

Precision Shaping and Surface Creation Through Multi-Axis Machining

Working with a Multi-Axis Machining Center can offer many advantages when it comes to precision shaping and surface creation. It offers the capability to maneuver around extended lengths, along multiple axes with great accuracy, allowing for complex shapes and surfaces that would not be possible with traditional machines. The Multi-Axis Machining Center is also capable of working on a variety of materials, meaning you don’t have to worry about lacking the right product for your job. Finally, it is cost efficient as well; you will save money compared to purchasing multiple single axis machines or accessories needed for other types of machining methods. The Multi-Axis Machining Center provides all the benefits in one comprehensive solution.

Working with a Variety of Materials with a Multi-Axis Machining Center

Multi-Axis Machining Centers are a valuable tool for working with a variety of materials. These machines allow for precise creation of complex shapes and surfaces, so regardless of the material you are utilizing, the same level of precision can be achieved.

Many manufacturers turn to these kinds of machines and their specialized software when creating custom orders or prototype parts, as they are reliable and cost effective.

This is advantageous to those who prefer high quality products that require short turnaround times – a combination that is not easy to find! Overall, the versatility and accuracy provided by Multi-Axis Machining Centers makes them an invaluable asset when working with different materials.

Cost Efficiency When Using a Multi-Axis Machining Center

Utilizing a Multi-Axis Machining Center can significantly reduce manufacturing costs due to its ability to simultaneously mill, drill, bore and cut intricate shapes with precision. This type of machine is cost effective as it can produce complex components in a fraction of the time and effort required by traditional machines. Moreover, because it can work on a variety of materials, such as aluminum, brass, and steel, less time needs to be spent changing machinery settings for different materials. Additionally, Multi-Axis Machining Centers help save money in labor costs due to requiring fewer employees to operate compared to multi-tasking systems that require several operations done by different machines. By investing in this type of system , businesses will be sure to see big savings in the long run.

Quality Control With The Use Of A Multi-Axis Machining Center

Adopting the use of a multi-axis machining center for quality control measures is an effective way to produce precise, repeatable components and parts. With its ability to create complex shapes and surfaces with accuracy and on a variety of different materials, you are able to ensure that any product manufactured is consistent in form and quality. This accuracy also allows for cost efficiency by the material waste that can be reduced or eliminated without sacrificing structural integrity. If you’re looking for an effective solution to improving your quality control management process, it may be time to consider investing in a multi-axis machining center.

Let’s work together

We produce results for our customers

Tips for Choosing the Right Multi-Axis Machining Center for Your Business

If you’re looking for the right multi-axis machining center for your business, there are a few important factors to consider. Firstly, research the features that the various options offer in order to determine whether they can be used for the specific tasks your business requires. It’s also important to look into the precision capabilities of each option and evaluate how quickly and accurately these machines can produce complex shapes and surfaces. In addition, make sure that the machine has the versatility to work on a diverse range of materials; this will limit downtime and minimize expenses. Finally, consider whether the cost efficiency of multi-axis machining centers makes them an economically viable choice when compared with other manufacturing solutions such as CNC milling machines and 3D printers. By taking all these considerations into account when weighing up your choices, you’ll be able to make an informed decision on selecting the perfect multi-axis machining center for your business.

Conclusion

Overall, Multi-Axis Machining Centers offer numerous advantages that make them a smart choice for any business looking to stay competitive in the manufacturing industry. Precision shaping and surface creation is one of the main benefits of using this type of machinery, as well as being able to work with a variety of materials. The cost efficiency offered by these machines is another attractive feature, as production time and costs can be greatly reduced when compared to other methods. With advanced quality control methods also built into these machining centers, businesses can rest assured that their products are consistently maintained for optimal performance. Now that you know the advantages of these Multi-Axis Machining Centers, it will be up to you to find the right one with the necessary features and capabilities for your specific business needs.