As a business owner, you’re always looking for ways to improve your bottom line. One of the best ways to do that is by investing in a Cost Effective Multi-Axis Machining Center. These machines offer a range of cost-saving benefits that can help your business stay competitive and profitable. In this article, we’ll take a closer look at some of the key advantages, and attempt to answer some of the most common questions about The Cost-Saving Benefits:

- Can your Multi-Axis Machining Centers help me reduce material waste and save on material costs?

- How does investing in a Cost Effective Multi-Axis Machining Center help me increase efficiency and productivity in my production processes?

- What kind of cost savings can I expect to see if I switch to using Multi-Axis Machining Centers in my business?

- How can a Cost Effective Multi-Axis Machining Centers help me reduce labor costs and free up my staff to focus on other areas of my business?

- What kind of precision and accuracy can I expect from your Multi-Axis Machining Centers, and how can this help me reduce costly mistakes and rework?

- Can your Multi-Axis Machining Centers help me expand my business capabilities and take on more projects, leading to increased revenue and profitability?

- How can your Multi-Axis Machining Centers offer greater flexibility and reduce the need for multiple machines, ultimately saving me money on equipment costs?

- Can you provide case studies or examples of how other businesses have saved money by investing in a Cost Effective Multi-Axis Machining Centers?

- How long can I expect your Multi-Axis Machining Centers to last, and how can this help me save money in the long run by avoiding frequent equipment upgrades?

- What kind of support and training can you provide to help me get the most out of my investment in your Multi-Axis Machining Centers?

What Are The Benefits Of A Multi-Axis Machining Center?

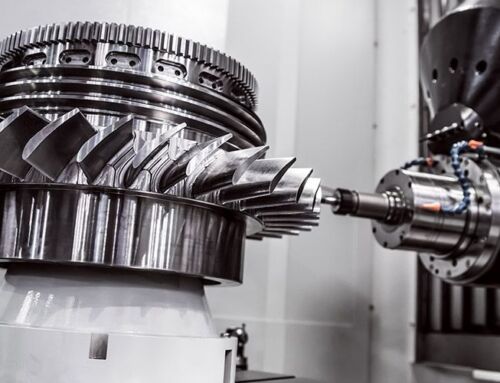

Before we explore the advantages, it’s essential to understand what they are. In essence, a Multi-Axis Machining Center is a type of CNC machine that has the ability to perform numerous operations in a single setup. Utilizing advanced software and cutting tools, these machines can create parts with exceptional accuracy and precision.

These machines are widely utilized across a range of industries, including aerospace, automotive, and medical, among others. They are particularly useful for producing intricate components that demand a high level of precision and accuracy.

Now that we know what Multi-Axis Machining Centers are, let’s explore some of the key cost-saving benefits that they offer.

This video shows an example of a multi-axis machine.

Increased Efficiency

One of their biggest advantages is the ability to increase efficiency. Because these machines can perform multiple operations in a single setup, they can produce more parts in less time. This increased efficiency can help your business save money by reducing production time and allowing you to complete more projects.

In addition, they can help reduce setup times. By automating many of the setup processes, these machines can help your business save time and reduce the risk of errors.

Reduced Material Waste

Another key advantage is their ability to reduce material waste. With their precision cutting capabilities, these machines can produce parts with greater accuracy, which means that there is less scrap material left over. This reduction in waste can help your business become more cost effective on material costs and disposal fees.

In addition, they can help reduce the amount of machining required to produce a part. By using advanced cutting tools and software, these machines can produce parts with a high degree of accuracy and precision, which means that there is less need for additional machining operations.

Improved Accuracy

Multi-Axis Machining Centers can be cost effective and also help improve accuracy. With their advanced software and precision cutting tools, these machines can produce parts with greater precision and consistency than other machining methods. This improved accuracy can help your business avoid costly mistakes and rework, which can add up over time.

In addition, they can help reduce the risk of human error. By automating many of the machining processes, these machines can help ensure that parts are produced with a high degree of accuracy and consistency.

Lower Labor Costs

Another advantage is their ability to lower labor costs. With their automated capabilities, these machines can perform tasks that would otherwise require skilled labor, freeing up your staff to focus on other tasks. This can help your business save money on labor costs, as you can hire fewer skilled workers or allocate your staff to other areas of your business. By automating many of the machining processes, these machines can help ensure that your workers are safe and protected while on the job.

Greater Flexibility

Finally, they can offer greater flexibility than other machining methods. With their ability to perform multiple operations in a single setup, these machines can produce a wide range of parts, from simple to complex. This flexibility can help your business expand its capabilities and take on more projects, which can lead to increased revenue and profitability, by reducing the need for multiple machines. In performing multiple operations in a single setup, these machines can help you consolidate your production processes and reduce the need for additional equipment.

Improved Quality

These cost effective Multi-Axis Machining Centers can also help improve the quality of your parts. With their advanced software and cutting tools, they can produce parts with a high degree of accuracy and consistency. This improved quality can help reduce the risk of defects, which can lead to costly rework and delays.

In addition, they can help you produce parts with complex geometries that would be difficult or impossible to produce with other machining methods. This can help you differentiate your business from competitors and offer unique solutions to your customers.

Longevity

Finally, these complex machines can offer a longer lifespan than other machining methods. These machines are often made from high-quality materials and components, which can help them withstand the wear and tear of daily use. This longevity can help you get more value out of your investment and reduce the need for frequent equipment upgrades.

Conclusion

In conclusion, Multi-Axis Machining Centers offer a range of cost-saving benefits for businesses of all sizes. From increased efficiency and reduced material waste to improved accuracy and lower labor costs, these machines can help you produce high-quality parts while saving time and money.

If you’re interested in investing, it’s important to choose a reputable supplier who can provide you with the support and training you need to get the most out of your investment. With the right equipment and expertise, you can take your business to the next level and stay competitive in today’s fast-paced manufacturing landscape.