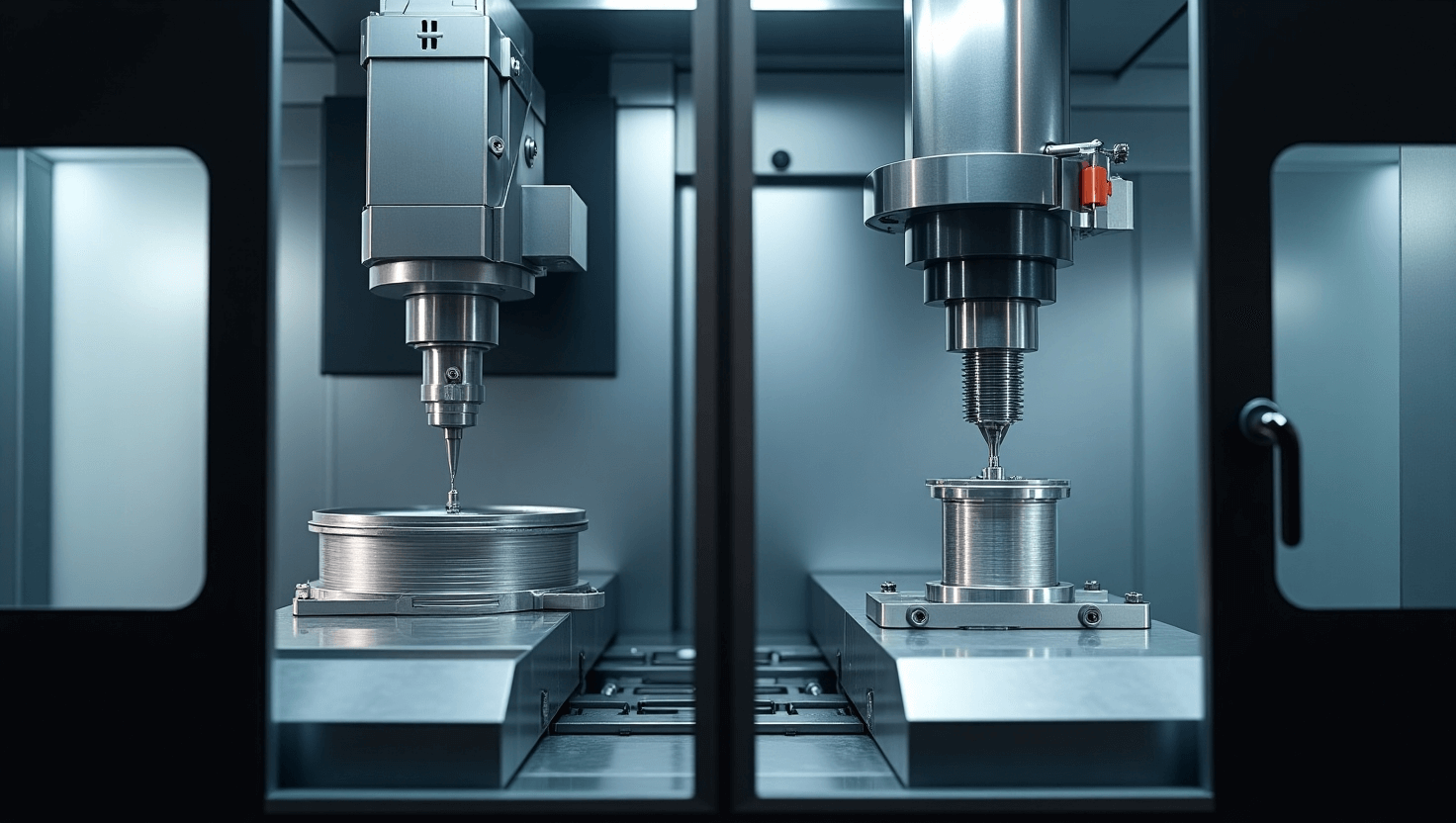

3-Axis vs 5-Axis Machining: know all the differences

When trying to buy a CNC machine, you will be bombarded with different kinds of machines that have different features. You will need to explore several brands, various types of CNC machines, and finally, machines with different numbers of axes. There are mainly two popular types of CNC machines when the number of axes is of concern: 3-axis and 5-axis. Both have their advantages and disadvantages, and both are good for different kinds of jobs, so which one can be the best choice for you? Let’s try to find that out. In this blog, we will dig deep into finding out the differences between 3-axis and 5-axis CNC machining.