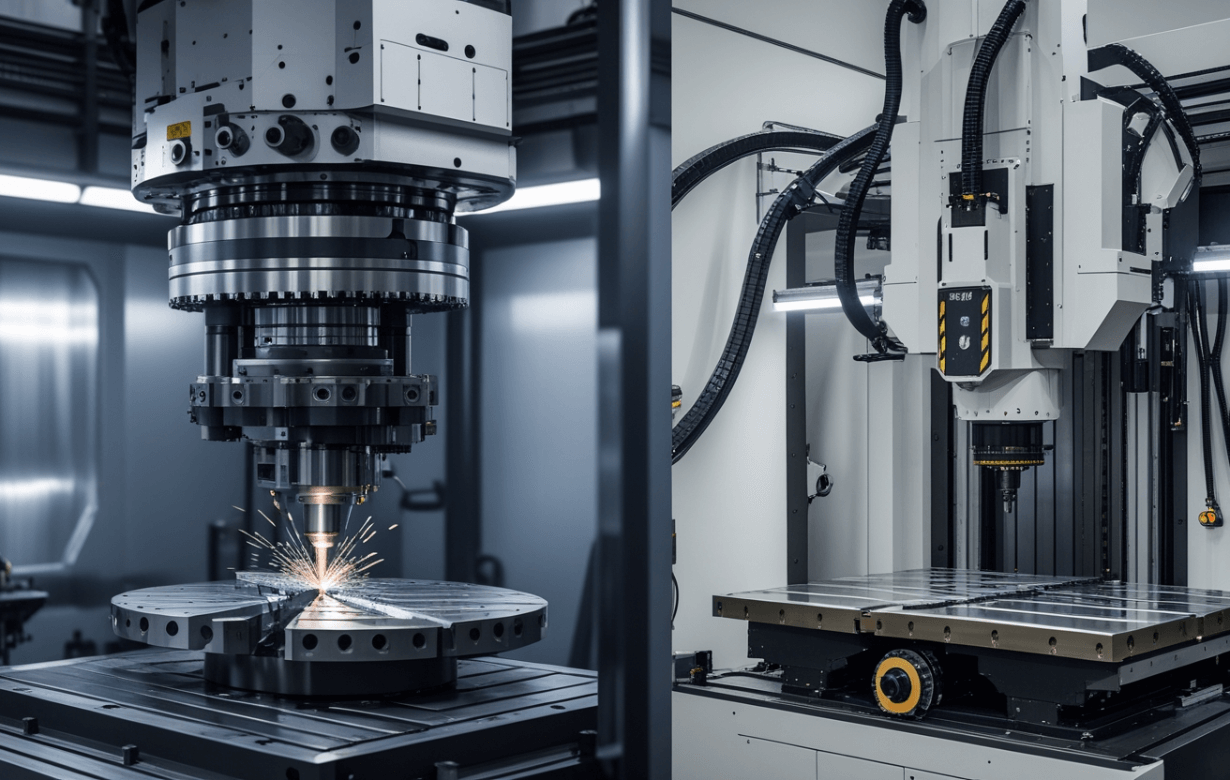

5-axis machining vs 7-axis machining

CNC machining has undergone significant advancements in the past few years, and one such development is the introduction of 5-axis and 7-axis machining. This has totally changed the definition of precision machining.

These machines are capable of machining a workpiece from various angles, which enables them to achieve unparalleled precision. The 7-axis obviously outperforms the 5-axis when it comes to precision machining, and complex geometry machining works.

But they have a lot of differences other than that. 5-axis machining and 7-axis machining are made for different machining purposes. If you’re curious about what the features of these two types of machines are, then you need to dive deep into the details with us to get a better understanding of which one will be better for your business.