1. Machine condition and history

Knowing the physical and operational condition, as well as the history, of the lathe is of paramount importance. You need to find out:

- What type of machining was the lathe used for? As lathes used for heavy duty machining will have more wear and tear compared to those that do operations with lightweight products.

- The number of hours used is also very important. There can be some used CNCs that are old by years but unused by hours, so try to look for such jackpot deals.

- Get the necessary records and documents about past maintenance and repairs that will help you understand how the machine was treated and also if there is a particular faulty part in the machine.

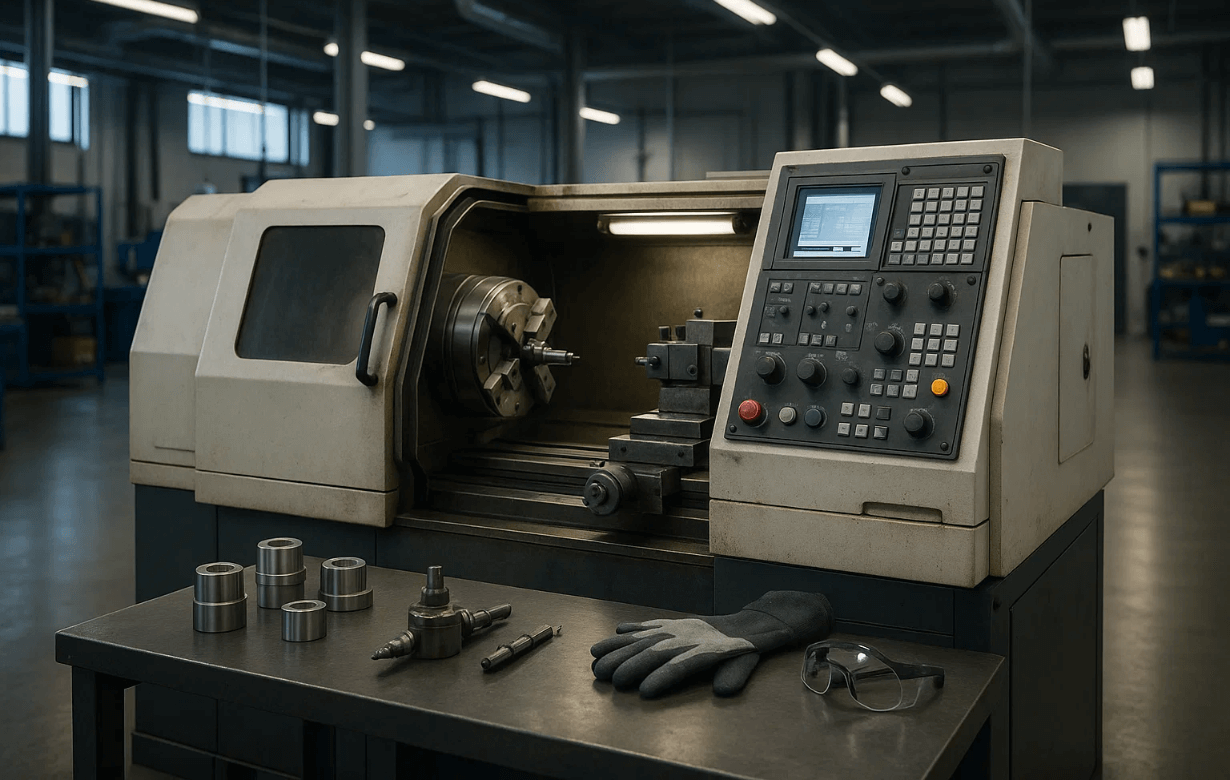

2. Structural integrity:

The next is the structural condition of the CNC Lathe which will also help in ensuring precision and accuracy in the machining of complex products. You need to make sure that the machine has that much structural strength to work as per your required tolerances. For that, you need to check the following things:

- Check the bed and ways, and inspect if there are any signs of cracks, wear, and damage. They need to be smooth because they guide the movement of the saddle and the carriage.

- Inspect if there are any unusual noises with the spindle or any vibrations that may hamper the surface finish.

- Make sure that the ball screws and the lead screws are free from any kind of wear and backlash otherwise that will lead to reduced precision.

3. Check key specifications:

Every lathe machine has its specifications depending upon the brand and the model, so check some of the important specifications to make sure you get the best as per your need. Here’s what are the things you need to know:

- First, check the spindle speed and power as that will help you determine the range of materials and also the weight of materials you will be able to machine with that lathe.

- Check the maximum turning diameter and length, which will help you determine the largest workpiece that the machine can handle.

- Ensure it has a good feed rate and accuracy because a high feed rate with accuracy will help you improve productivity and part quality.

- Also, check the number of axes in the machine as a higher number of axes gives you the comfort to machine the most complex of geometries.

4. Software and Control system:

The next is checking the control system of the lathe, as they are the brains of the CNC machines. Make sure that the control system is updated and also compatible with the CAM software that you use. You also need to check these things:

- Ensure that the controller is of a well known brand, has a user friendly interface, and supports the necessary programming capabilities.

- You will also have to check whether the controller is compatible with your existing CAD/CAM software, outdated ones may damage your programming capabilities.

- Also, inquire about the availability of software updates and technical support for the specific control system of the lathe.

5. Tooling and accessories:

You need to verify what tooling and accessories are associated with the lathe that you are planning to buy. Assess several things about the tooling of the machine, like:

- Check the tool turret capacity, find the number of tools the turret can hold and switch between.

- Ensure that the machine can support the size and types of tools that you are planning to use.

- Check what accessories are available with the machine like follow rests, chucks, steady rests, and other essential things.

6. Automation and ease of use:

In modern times, lathes are highly advanced so find machines that can adapt to automation features and then compete with new models. Inspect the following things for that:

- Try to find a machine that is compatible with automation integration like bar feeders, part catchers, and automatic tool changers.

- Ensure that the machine has an easy interface and not so complex features which will ensure ease of use and also minimize the learning curve.

7. Documentation and manuals:

Getting the necessary documents is very important for future operations and maintenance of the CNC machine. Here are the things you need to check:

- You must get the accuracy and calibration certificate from the manufacturer.

- Get the records of retrofits, major repairs, and crash history, if any.

- Find the operator manual too, that is going to be essential for employee training and troubleshooting.

- Check the electrical schematics which are useful for future repairs and upgrades.

8. Brand reputation:

When you have selected a machine that matches all the previous points, then you need to verify whether the brand is good for you or not. The brand of the lathe can directly influence its reliability and support. So, here are the points you need to ensure:

- Try to buy CNC lathes of well known brands and their high end models, as they come with a reputation and reliability.

- Buying machines of reputed brands also ensures the fact that you get readily available spare parts.

9. Platform reputation:

Though it is not a feature of the CNC lathe it is still very important. Where you are buying the machine from is as important as which machine you’re buying. You need to get your used CNC lathe from a reputed platform that will bring reliability and trust to the table. Here are things you need to look for in a used lathe selling platform:

- They have a good team that will help you understand the basics about the machine, and suggest you the best machine.

- They will help you with the delivery of the machine to your facility.

- They are a reputed platform with experience of doing this job for a long time.