How Long Do CNC Machines Last

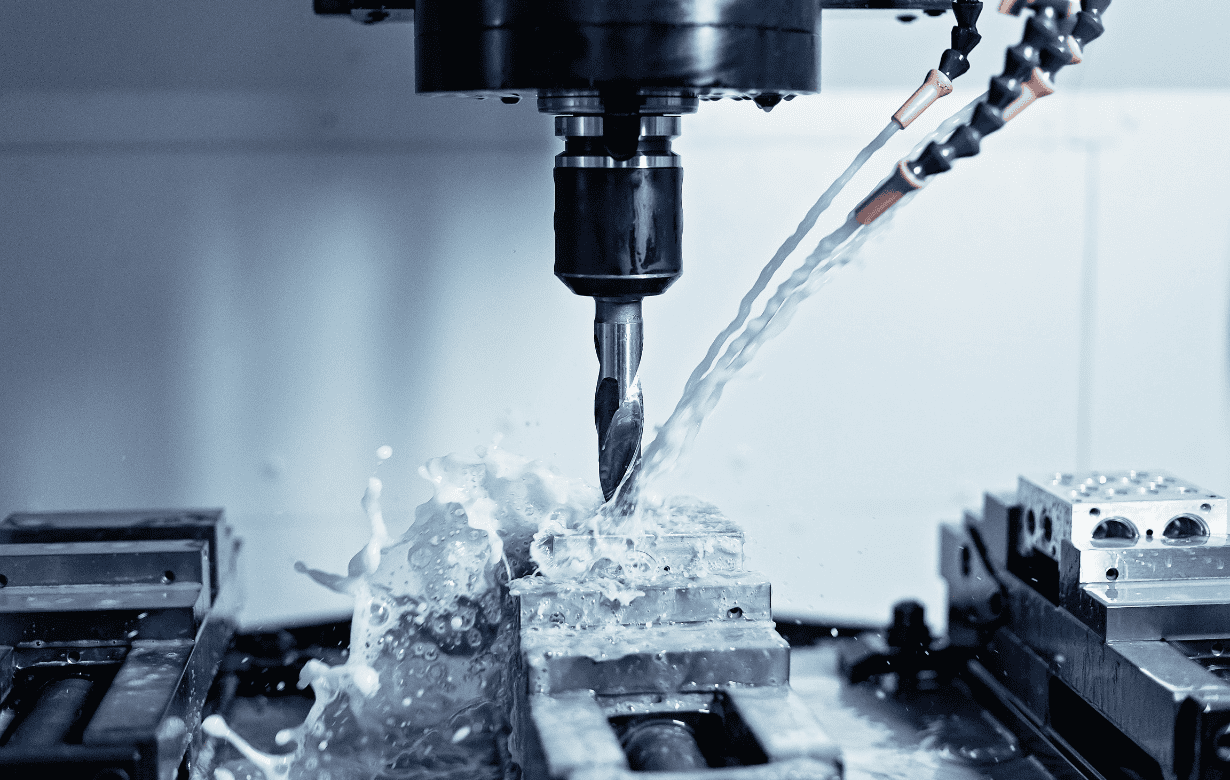

CNC machines are among the most important components of manufacturing plants. They undergo a lot of machining work daily, which is why they often show some wear and tear and other technical problems. However, these machines are still pretty reliable and long-lasting.

The age of a CNC machine is generally between 10 and 20 years. But sometimes, the machines run even for longer years if you take proper care of them and do regular servicing. Also, several factors determine the lifespan of a CNC machine, like the brand of the machine, frequency, and intensity of machine usage, and regular maintenance and upgrade of the control system.