CNC Machine Software Updates: What You Need to Know Before Upgrading

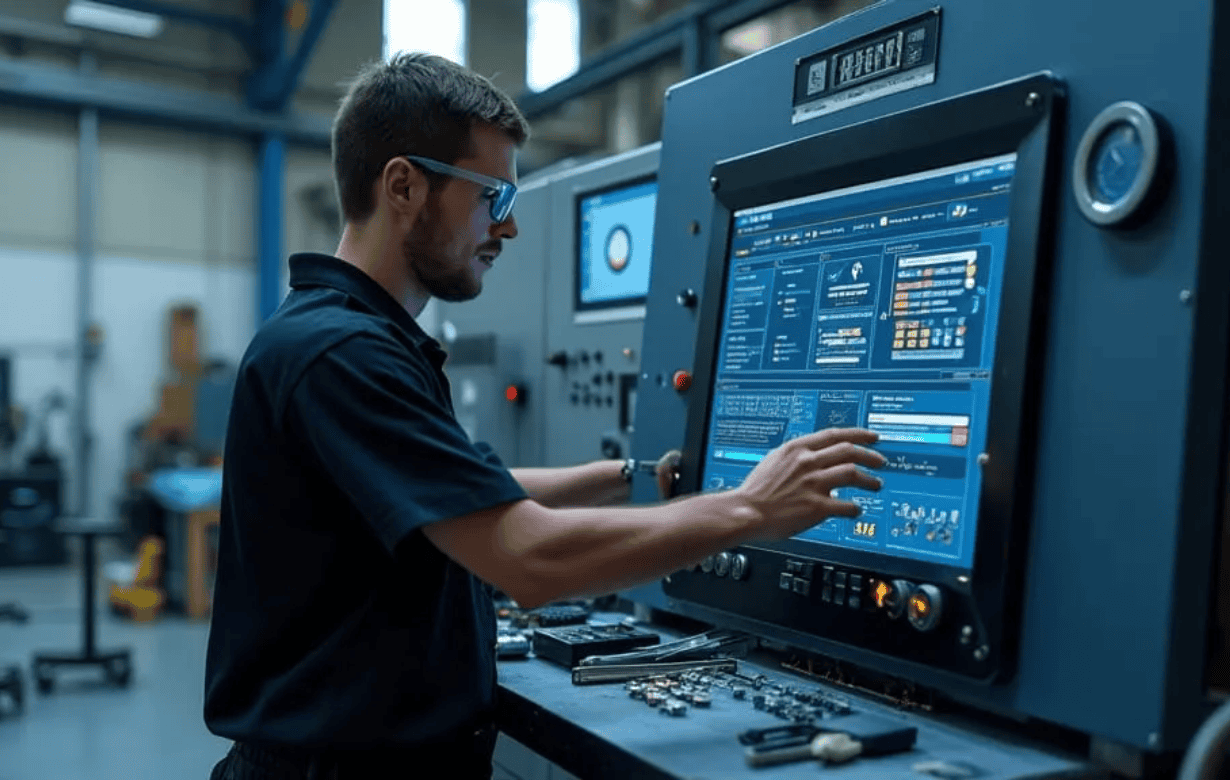

The control system software of a CNC machine is one of the most important parts of the machine. Like CNCs are the backbone of a manufacturing setup, similarly, the control system software of a CNC is the backbone of the machine. These software systems often give update notifications, and these updates help your machines to be more tech efficient and make the whole machining process easier. But like everything else, it has its drawbacks too, and that’s why you need to be very careful while deciding on the software update of your CNC machine.