How to Prevent Downtime with a Used CNC Machine

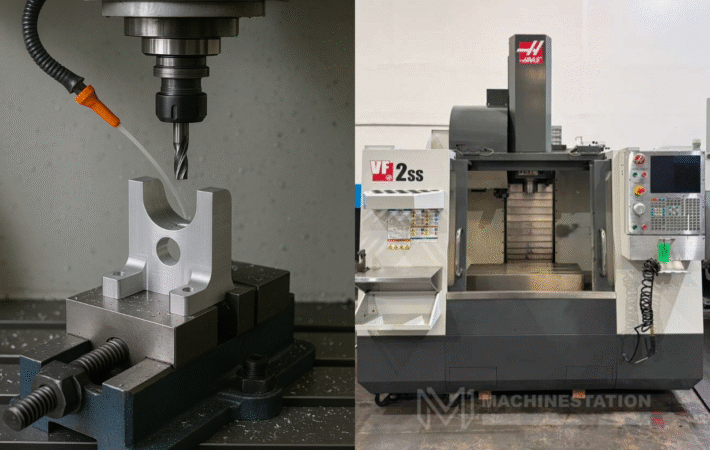

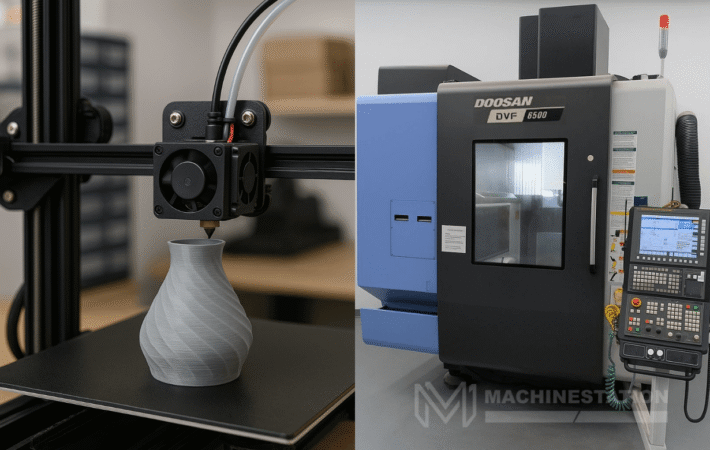

CNC machines are the rockstar machines for any manufacturing business, as they help you do the most complex of engineering works without any hardcore labour work from your side. When you buy a used CNC machine you also get a financial advantage as the machine gives you all the benefits at a lower upfront cost.

But there is a silent killer that can destroy all your financial gain plans that you thought regarding the CNC machine and that’s downtime of the CNC machine. If your machine is sitting idle or is not able to work due to internal technical problems or any kind of wear and tear then that will cost you heavily on a financial basis. You will lose on production against your competitors, miss deadlines, and damage your relationship with clients. So, if you don’t want such things to happen and prevent downtime then read this blog till the end.