CNC machines are one of the most widely used tools in the world by every manufacturing business. These tools have made the whole manufacturing process simpler, and with more modern automation features getting added to these machines, the process of manufacturing is destined to be easier and better in the future. These machines are helpful for businesses in several sectors which include wood, plastics, titanium, steel, and many more. There are different types of CNC machines for different industrial needs. Now, if you are curious about it or looking to buy one for your business, then read our list to know which one will be best for your business.

Different types of CNC machines

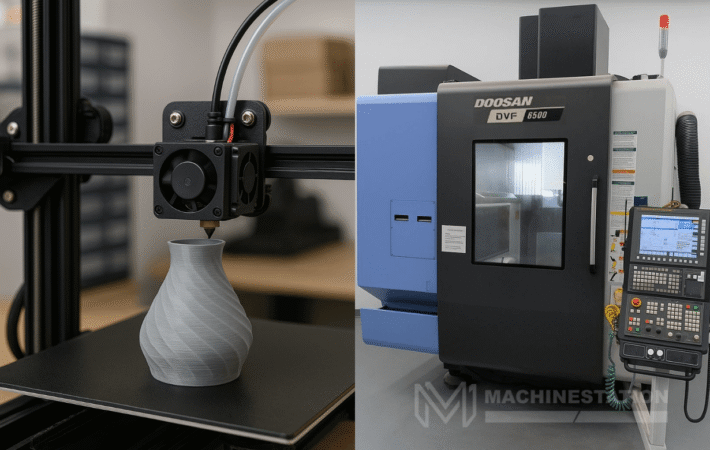

There are different types of CNCs with different types of features that serve different industries. So, here’s a list of some of the most important types of CNC machines that you need to know before you buy one –

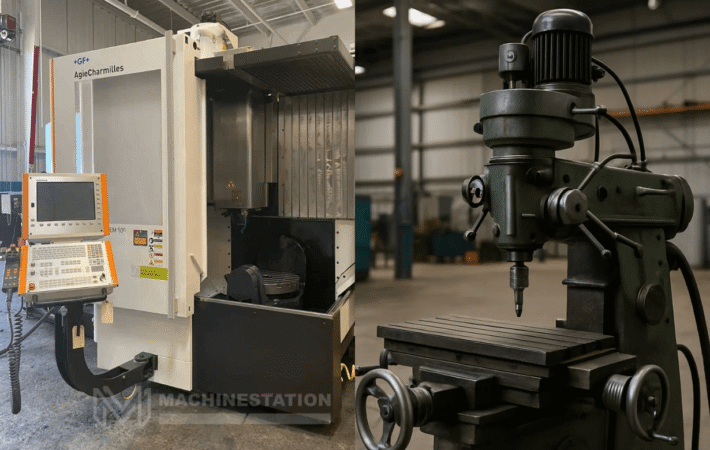

- CNC Milling Machines – The first name that comes to mind on the list of CNC machines is milling machines. This is one of the most versatile types of CNC machines, which uses rotary cutters to remove materials from a workpiece. The main feature of these milling machines is that they can move the material and the cutting tool relative to each other along multiple axes. They generally operate with 3 or 5 axes, while 3-axis machines are the most popular ones. There are four axes milling CNC machines too, which incorporate one rotatory axis (A-axis).

Other than that, the CNC milling machines can also be classified into two parts as vertical CNC milling machine and horizontal CNC milling machines. In vertical machines, the spindle is oriented vertically, and it is oriented horizontally for horizontal CNC milling machines.

These machines are suitable for both metal and plastic products for different industries like automotive parts, precision molds, and dies. They mainly perform operations like drilling, boring, and tapping. - CNC Lathes – The next type of CNC machines that are also very popular among customers are the CNC lathes. These machines are also known as CNC turning machines, and they are the perfect machines for the manufacturing of cylindrical or symmetrical parts. Advanced CNC lathes also feature multiple axes, like 4 or % axes, for more complex operations.

There can be different types of CNC lathes, too. The first type is the dual axes CNC lathes, which are also the most basic types and help in turning operations along the Z and X axes. Then there are also multi axes lathes with a C-axis for indexing the workpiece. Lastly, there are swiss type lathes which are designed for machining small, intricate parts with precision.

They perform turning, threading, and facing operations with materials like metals and plastics. They help in the manufacturing of shafts, bearings, aerospace parts, etc. - CNC Routers – The third type of CNC you need to know about is the CNC Routers. These CNC machines are quite similar to the milling machines, but it is actually used for cutting softer metals, and often sheet-like materials like wood, plastics, and composites.

There can be different types of CNC routers, like gantry routers. These routers have a gantry structure that spans the worktable, and the spindle moves along the gantry. Then comes the moving table routers, where the worktables move beneath a fixed gallery and spindle. Lastly, there can be nested-based router CNC machines, which are specifically designed for processing different sheet materials.

These machines are great for different furniture manufacturing, prototyping and mold making, sign making, and engraving, etc. The main advantage of this machine is that it is fast and can easily handle large workpieces. It also comes at a lower price compared to heavy-duty metalworking machines. - CNC Plasma Cutters – The next machine that we are going to talk about is the CNC plasma cutter. These machines use a high speed jet of hot plasma to cut through different electrically conductive materials like aluminum and stainless steel. The whole process involves the creation of an electrical arc that ionizes a gas, forming plasma with extremely high temperatures.

These machines are widely popular for their capability of cutting through relatively thick materials. CNC plasma cutters are also capable of producing complex and detailed engineering parts. However, they are not suitable for nonconductive materials, and the edge quality may require secondary finishing.

These machines are used for metal fabrication, construction, aerospace components manufacturing, artistic metalwork, and sculpture. - CNC Laser Cutters – A CNC laser cutter does the machining operation by utilizing a focused laser beam to cut or engrave materials with high precision. The highly focused laser light is used to melt, vaporize, or melt material along a programmed path. The type of laser used totally depends upon the material being cut and the desired thickness and precision.

The main advantage of these machines is that they provide an exceptional level of precision regarding the cutting of tools. These machines help in making products with clean cut edges, and also in cutting a wide range of materials into intricate shapes. They are used for both cutting and engraving operations. The non contact process of these machines also reduces wear and tear of tools. But the limitation of this machine is that it can work with a limited thickness of materials only.

These machines are mostly used for electronics manufacturing, jewelry making, medical device components, and precision sheet material fabrication. - CNC EDM (Electrical Discharge Machining) – The last name in the list is the CNC EDM machines. These machines are also known as spark erosion machines, and they use electrical discharges to erode material from a workpiece. This process allows for the creation of intricate shapes and fine details in hard metals.

There are actually two different types of EDMs – the first type is the Wire EDM, which is about a thin electrically charged wire fed through the workpiece, which further creates sparks that erode the material along the programmed path. The second type is the Sinker EDM, where a shaped electrode, which is made up of a conductive material, gets plunged into the workpiece, which creates sparks, helping to erode a cavity mirroring the shape of the electrode.

These machines are very good for creating complex parts, but are slower than traditional CNC cutting methods. They are used for tool and die making, medical device manufacturing, and aerospace materials with tight tolerances.

Conclusion

There are also some other types of CNC machines, but these six are the most commonly used ones and can help you in getting your work done. Now, if you are planning to buy one of these it may not be a good option for you to go with a new CNC due to high upfront costs but you can buy the used ones at a reasonable price from MachineStation.