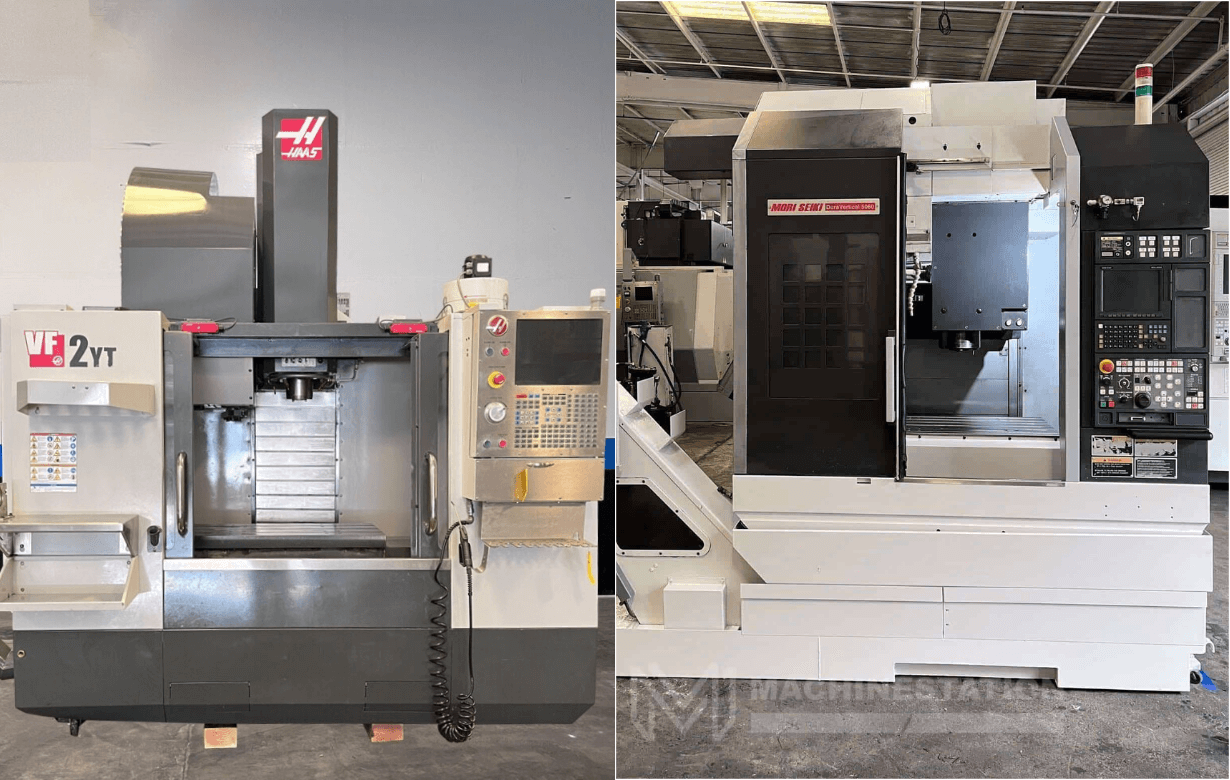

Haas vs DMG Mori – Which one is better?

Haas and DMG Mori, are two brand names that need no introduction to machining enthusiasts or people who use CNC machines. The brands have been ruling this market for several decades now with their high quality but they both have very distinctive features and are good for different genres of businesses. But how are you going to find which one is good for your business? You are going to find that out once you read our article here.