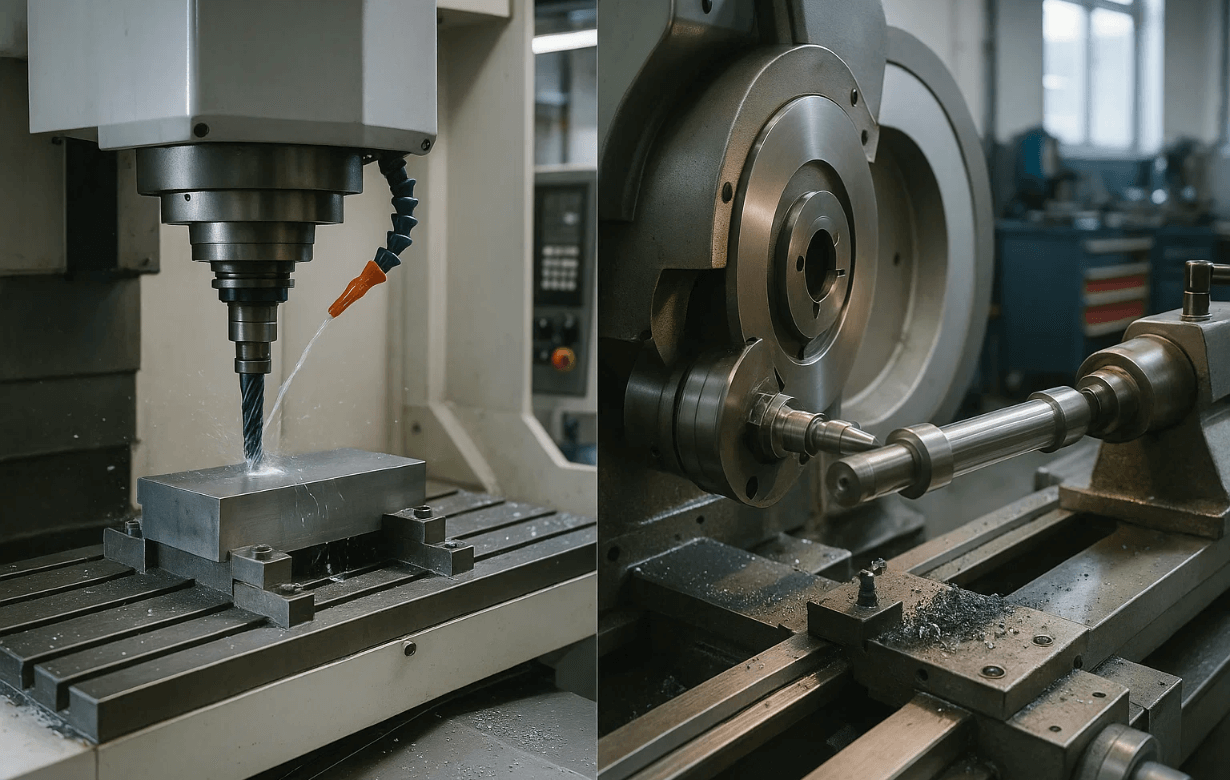

Can a CNC mill replace a Lathe?

In the world of machining, different types of machines are used for different reasons. Some stand out because of the materials they can work with and some stand out for the kind of product they can produce. Two of the most common types of CNC machines that are used by different companies around the world are CNC mills and CNC lathes. Both of these machines are highly efficient for the job they are meant to do. But through this blog, we will try to understand whether a mill can do the job of the lathe. If you are curious about this topic then let’s continue with us till the end and we will help you out.