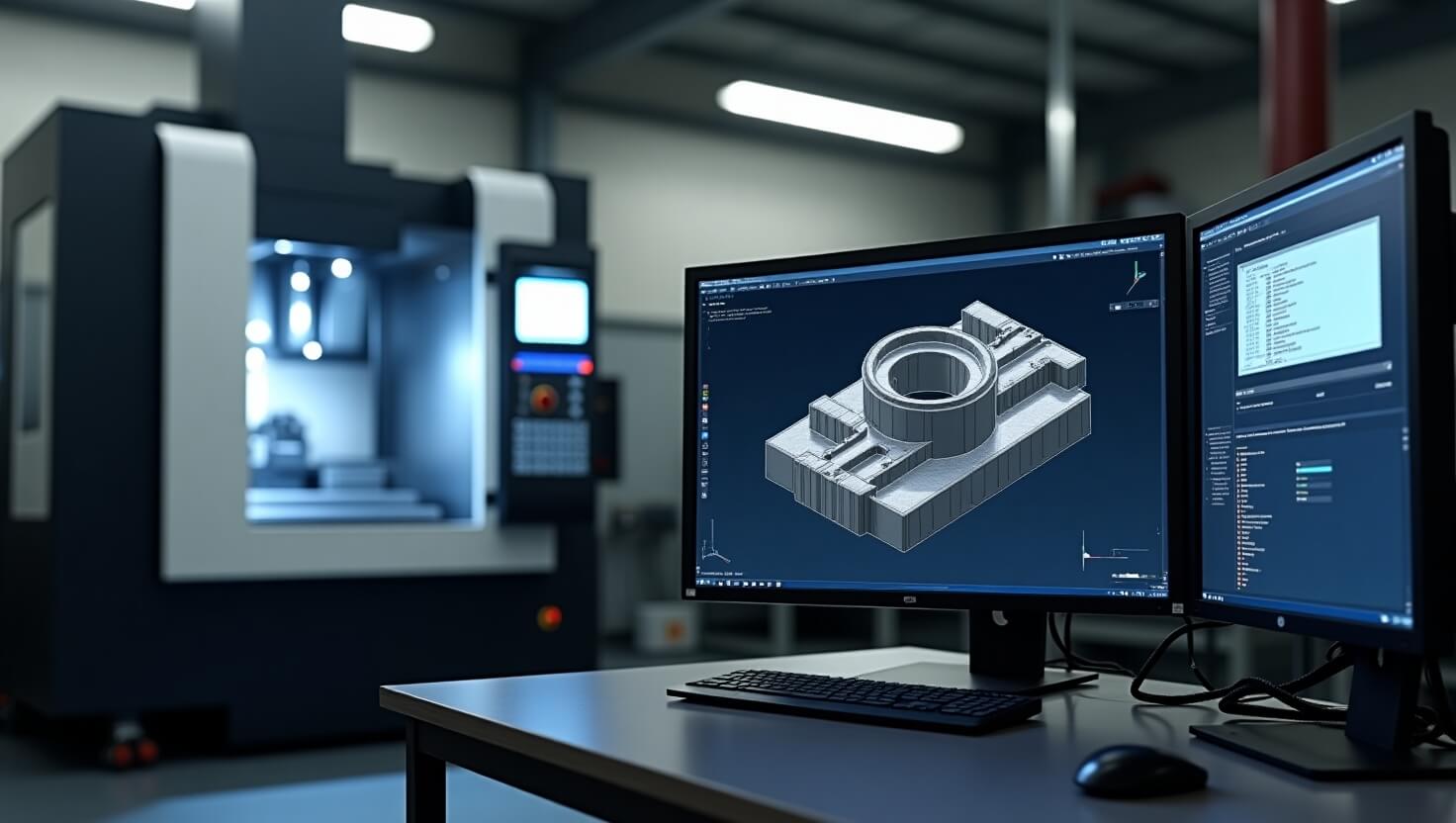

What Software Do CNC Machines Use? (Top CNC software options)

CNC machines are the backbone of modern manufacturing. Whether you are using a new CNC or buying a used CNC machine, you can get any precise manufacturing work done as per your business requirements. But no matter which brand of CNC you are using or how many axes the machine has, one thing you need to be very careful about is what software is being employed in the CNC machine. The software can be the most important determinant of your machining experience, as it can decide how seamlessly you will be able to carry out the entire machining process. In this blog, we will talk about all the well-known software that is used in CNC machines, and you can choose one among them for the best machining experience.