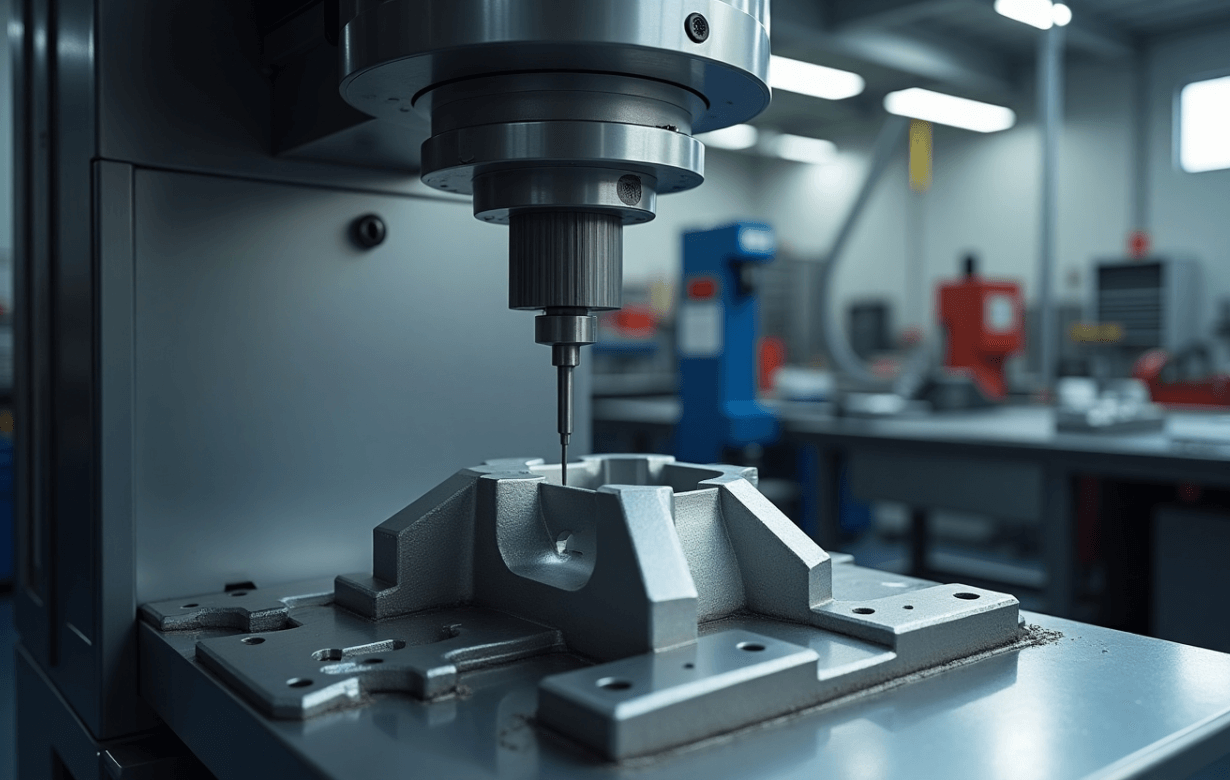

CNC Machine for Brake Calipers

CNC machines are now the go-to option for machining shop owners for any product manufacturing. The scenario is no different for brake caliper machining, as a well-functioning CNC machine is required to manufacture brake calipers. However, the main question is, what type of CNC machine, among all its types, is needed for brake caliper manufacturing? The direct answer to this question is a 5-axis machining center, which is the type of machine needed for machining brake calipers.