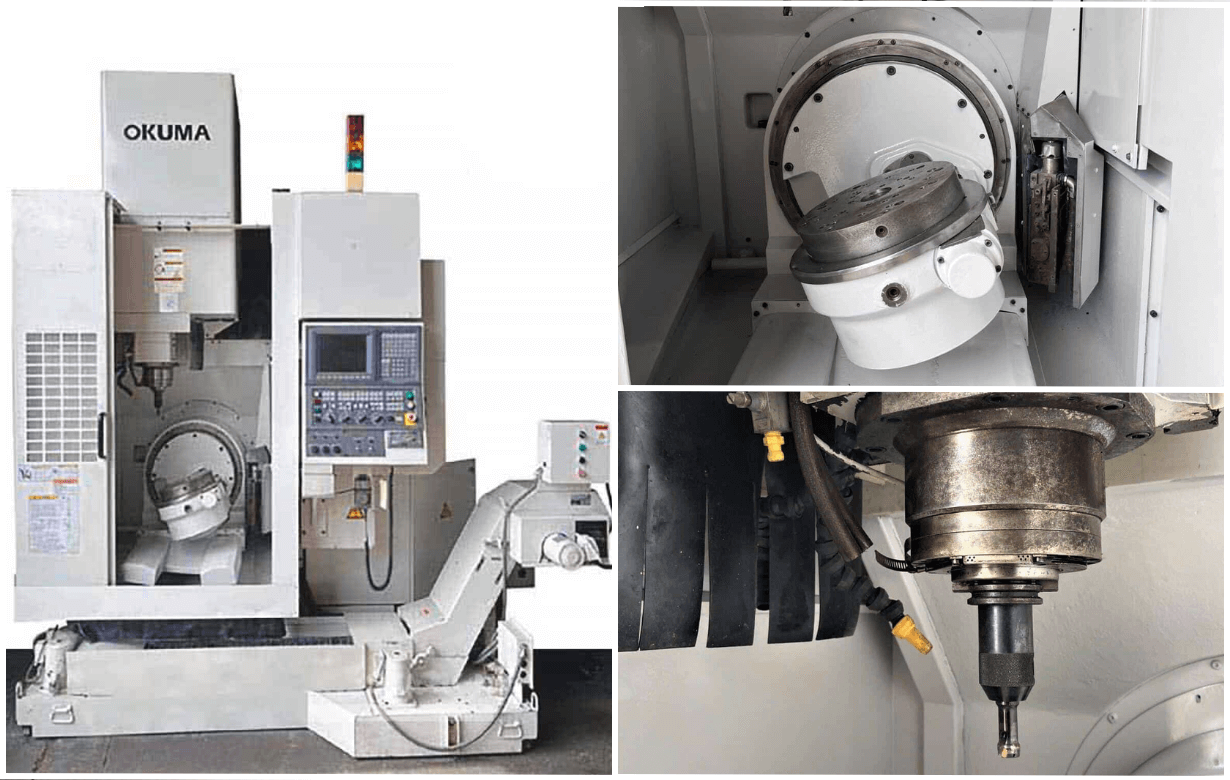

Best Okuma Model For Heavy Weight Machining

Okuma is a leading CNC brand known for its high-precision, durable machines that handle both lightweight and heavyweight materials with ease. Its advanced technology and reliability have made it a trusted choice for major manufacturers worldwide.

Because many industries work with heavy materials, Okuma’s heavyweight-capable CNC models are especially popular for their power, stability, and consistent performance. If you’re looking for the best Okuma machines for heavy-duty machining, you’re in the right place.