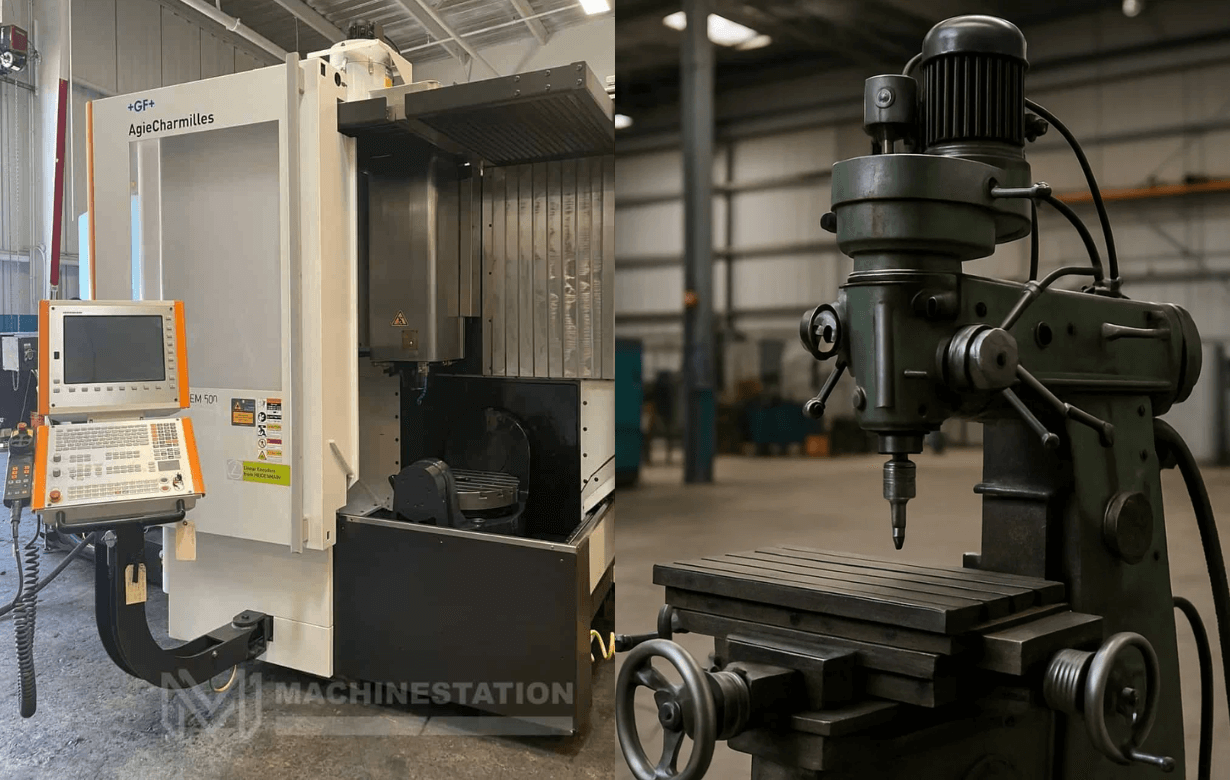

Top Advantages of CNC Machining:

CNC machining offers numerous advantages for all machinists. Here are the main advantages that you need to know about:

1. Superior Precision:

One of the key advantages of using a CNC machine is the superior precision that it can bring. The high end CNC machines can provide micron level accuracy in machining, helping shops to make intricate parts easily.

2. Better Productivity:

The CNC machines are much faster than manual machines, and they can work 24*7 without the need for any human intervention. This helps the machining shops produce more products in a short period of time, and this is one of the major uses of CNC machine.

3. Repeatability:

If you want to get into a high volume production business, then CNC machines become hugely beneficial for you, as you can produce multiple parts at a continuous speed with maintained uniformity in part precision.

4. Better Safety:

One of the major CNC and manual machining differences is the advantage of safety in CNC machining. There is minimal human intervention in CNC machining, which makes it much safer for operators.

5. Reduced Material Waste:

In CNC machining, the toolpath is optimized as per the codes, which helps in smooth cutting of the workpiece to reach the accurate shape in one pass, which reduces the material waste due to less scrap.

6. Lower Labor Cost:

CNC machines do their jobs in an automated manner with minimal need for operator intervention, which helps the machining shops to reduce labor costs and optimize for more financial efficiency.

7. Complex Geometric Capabilities:

CNC machines can make complex geometric products with ease. The machine can make products with intricate designs, which are impossible with manual machining, and it is one of the major uses of CNC machine.

Drawbacks of CNC Machining:

Though it has many strengths, CNC machines have their own drawbacks too. Here’s the list of the major drawbacks of CNC machining:

1. Higher Initial Investment:

One of the major drawbacks of CNC machines is their high initial price. This becomes a setback for CNC machines in CNC vs manual machining because not every machining shop can afford a super costly machine.

2. Skilled Programmers:

To run a CNC machine, you need a skilled programmer who can write the right code that will instruct the movement of the tools of the CNC machine. This adds training time and costs for every machining shop.

3. Costly Maintenance and Repair:

CNC machines can be repaired only by well-trained technicians. So, when the machine stops working for some reason, you need to wait for the right technicians to reach and troubleshoot the issue, which increases the downtime of the machine.