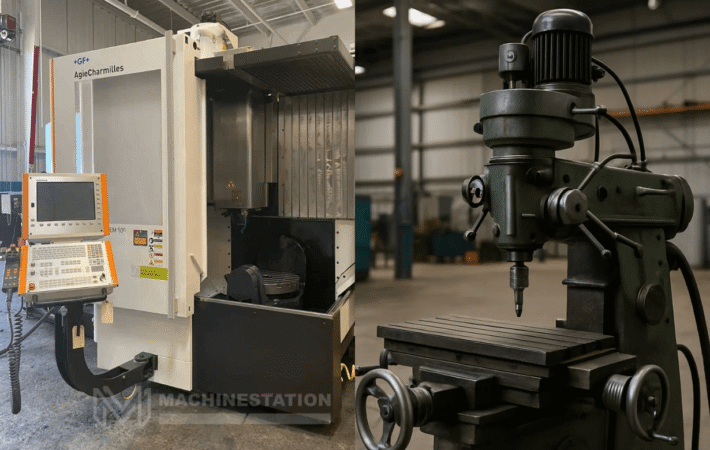

The world of manufacturing has been totally transformed with the help of CNC machines, and among all the different types of CNC machines, the CNC mills and routers have been hugely popular among machinists around the world. At first glance, both the machines might look the same to you, but they have very different features and cater to different needs and materials. So, if you’re also confused between CNC router vs CNC mill, and which one should you choose for your machining shop, then this is the right page for you, as we will discuss the main differences between CNC router vs mill in this blog.

CNC Mill vs CNC Router – What are the Main Distinctions?

Let’s dive deeper into finding out what are main differences are between CNC milling vs routing that you need to know:

Definitions:

CNC Mill: CNC mills are the machines that are used for precision cutting, shaping, and engraving for different soft and hard materials, which include metals, plastics, and composites. They are designed for high precision, tight tolerances, and complex geometries. These machines prioritize rigidity and precision over speed.

CNC Router: CNC routers are used for machining, shaping, cutting, and engraving softer materials such as wood, plastics, foam, and aluminum. These machines are well celebrated for their high speed and cover larger work areas. These machines are mainly focused on high speed machining over rigid machining of strong materials.

Key Components and Construction:

Component CNC Router CNC Mill Frame/Bed Large, flat, less rigid Heavy, rigid, absorbs high cutting forces Spindle High-speed, lower torque Lower speed, high torque, robust Tooling Router bits, V-bits, ball nose End mills, face mills, drills, reamers Workholding Vacuum tables, clamps Vises, fixtures, T-slots Axis Drive Rack-and-pinion or ball screw Ball screw (for high accuracy and rigidity) Tool Changer Optional (ATC in high-end models) Common in industrial mills Coolant System Rare Common, especially for metal cutting Materials Each Can Handle:

CNC Mill Material Strengths:

- Wood, plywood, and engineered wood products

- Plastics, including acrylic, PVC, and polycarbonate

- Foam and composite materials

- Soft metals like aluminum and brass

- Non-ferrous metals in lighter applications.

Advantages: Can cut different solid materials with tight tolerances and pinpoint accuracy.

Disadvantages: Slower machining speed compared to routers.

CNC Router Material Strengths:

- Hardened steel and stainless steel

- Titanium and titanium alloys

- Tool steel and high-strength alloys

- Cast iron and heavy metals

Advantages: Can easily cut softer materials with high machining speed.

Disadvantages: Struggles in cutting demanding materials and maintaining tight tolerances.

Accuracy and Precision Levels:

Precision is the area where the CNC mill gains an advantage in the CNC router vs CNC mill debate. High end mills from top brands can achieve micron level tolerances. Routers are also known for maintaining accuracy for general machining tasks, but fall short for intricate designing work.

Advantages of CNC router: These machines can provide sufficient precision for engraving and shaping with moderate tolerances.

Disadvantages of CNC router: Not suitable for micro machining operations.

Advantages of CNC mills: Superior repeatability for high stakes applications with demanding materials.

Disadvantages of CNC mills: Needs more trained individuals for calibration and maintaining that precision edge.

Axis Configurations:

The axis configurations of CNC mill vs CNC router machines are important because they determine the versatility of the machine and its ability to do complex machining operations. Most routers operate with 3 axes, and the modern ones can go to 5 or 6 axes. But the mills can go up to 12 axes, giving them the ability to do the most complex operations in just one setup.

CNC routers: They are easier to set up due to simpler axis configurations and need less programming.

CNC Mills: More axis needs better software and programming skills, but they help with machining of complex parts in one go.

Machine Rigidity and Construction:

CNC Mills: The CNC mills get an advantage in this debate of CNC milling vs routing machines with their strong rigidity. Their key rigidity feature includes:

- Heavy cast iron or steel bases that help in absorbing vibrations.

- Precision ball screws with minimal backlash.

- Robust spindle assemblies that help in resisting deflection.

- Hardened steel guideways with minimal play.

CNC Routers: These machines have a lighter construction, which enables the moving gantry design. The modern routers incorporate structural reinforcements and quality linear guides; their inherently cantilevered gantry design makes them less rigid than mills. The lighter construction is not a disadvantage considering the applications of the machine, but actually benefits the buyers with easier loading and unloading.

Cutting Speed and Feed Rate:

Aspect CNC Router CNC Mill Spindle Speed (RPM) 10,000-30,000 RPM 1000-15,000 RPM Feed Rate 100-500 IPM 10-100 IPM Cutting Depth Per Pass Shallow Deep Cycle Time Faster for soft materials Slower but more powerful cuts

Which One Should You Choose – CNC Router vs Milling Machine?

Choose a CNC router if you:

- Primarily work with wood, plastic, and composite materials.

- Want more affordable entry to CNC machining.

- Have limited floor space but need larger work areas.

- Your focus is on speed and large format production.

Choose a CNC mill if you:

- Work with hardened steel, stainless steel, and titanium.

- Wants to maintain tight tolerances and precision in machining.

- Works with smaller and more complex three dimensional products.

- Need the rigidity to handle heavy cutting forces.

Conclusion:

CNC router vs CNC mill is a very debated topic, where choosing the right machine is a job that can only be done by you. There are several CNC router benefits and several CNC milling benefits, so select the one that fits your machining needs the most. Also, don’t forget to check the huge collection of used CNC machines at MachineStation before making the purchase decision.

FAQs:

Q1. Can you use a CNC router as a mill?

Ans: CNC Routers are used for other materials compared to mills. So, if you want to machine hard materials, then we won’t recommend using a CNC router as a mill.

Q2. Is milling the same as routing?

Ans: Though their machining technique is the same as rotating tool cutting workpiece, still the materials these machines can work on are totally different.

Q3. What is the difference between a router and a mill?

Ans: The main difference between a CNC router and a mill is that a router cuts softer materials, while a mill is used to cut harder materials.