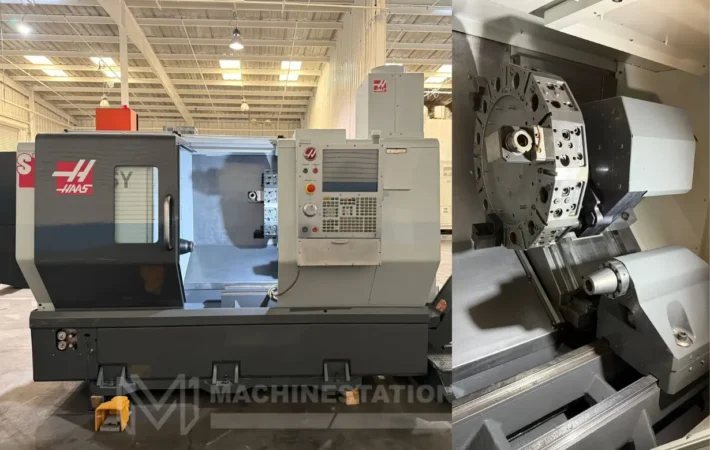

AI-Powered Predictive Maintenance for CNC Machines

AI has made a lot of changes in the world of manufacturing and CNC machines, from helping to generate code without coding to AI assisting in the creation of a digital twin for better simulation of the machining process. But, one more thing has changed with the help of AI in the CNC machining world, and that is the adaptation of predictive maintenance in different shops. AI predictive maintenance for CNC machines is becoming hugely popular because of the different benefits it provides. So, in this article, we are going to discuss everything about AI predictive maintenance in manufacturing.