Haas VF-2D vs Haas VF-2

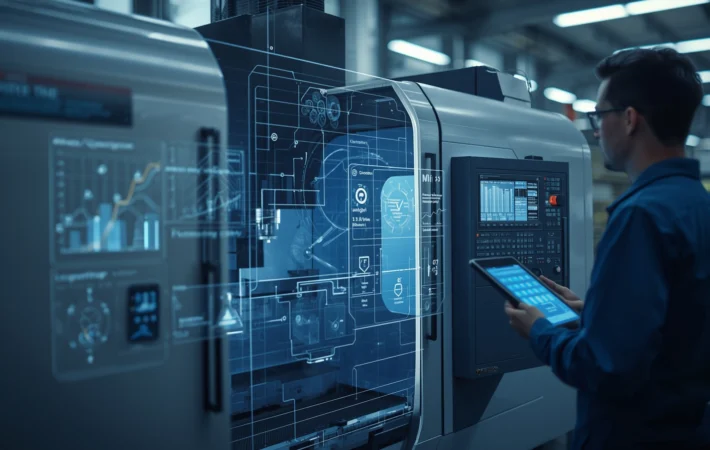

The Haas VF series is a well-known lineup of top-notch CNC machines used by manufacturers across various industries for a wide range of applications. Among the various machines in the VF lineup, the Haas VF2D and VF2 are two of the most popular names. But these two machines have different purposes of machining, and should be used by different manufacturers. So, which one is suitable for your manufacturing needs? To find that out, you should read this blog to the end and know which one among Haas VF 2D vs Haas VF2 is the right choice for you.