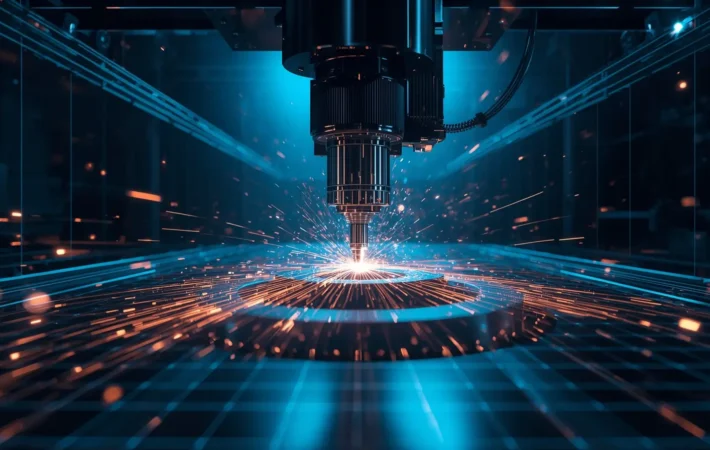

How to Reduce Scrap Rates in CNC Machining Operations?

A hidden factor that increases the cost of CNC machining shops and decreases their profit margins is the scrap rate. In the crowd of labour costs, machine maintenance costs, and high material costs, this factor often goes unnoticed. However, shops can get rid of these issues very easily by following the right strategies. Scrap leads to different problems like more machining time, loss of raw material, more labour hours, and damage to cutting tools. So, if you want to reduce scrap rates in CNC machining, then read this blog till the end to know the best strategies.