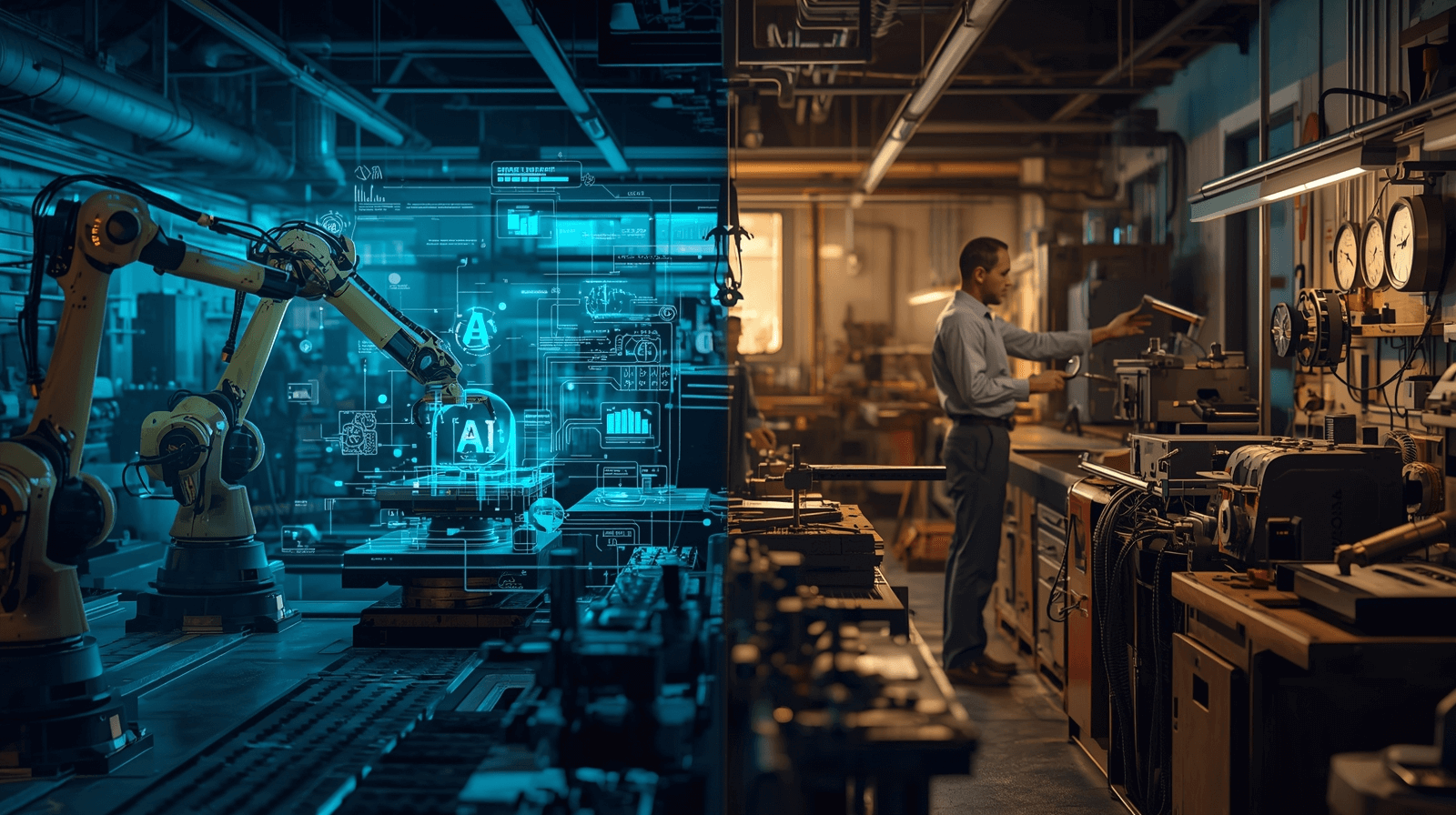

AI vs Traditional Manufacturing: Key Differences and Advantages

AI is changing every industry in the world, and manufacturing is no different. Traditional manufacturing methods are now being impacted with the help of automation. AI manufacturing methods are now being used by different machining facilities in place of traditional manufacturing methods, but they have their own drawbacks, too. So, it is very important to realize both the differences and advantages of both AI vs traditional manufacturing so that one can make the right decision. In this article, we are going to discuss all the differences between traditional and AI-based manufacturing, so that you can make the right decision about choosing the right machining method for your business