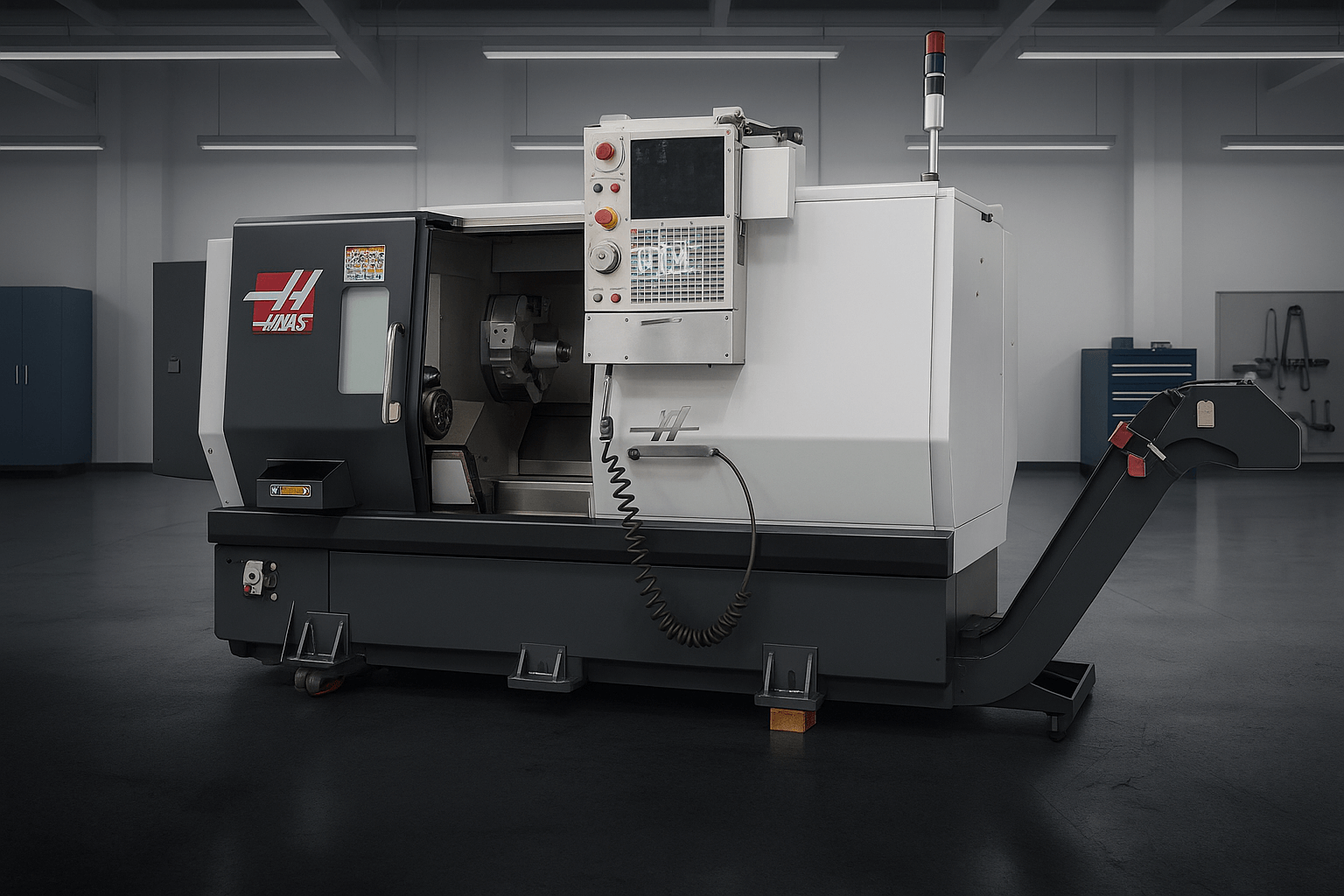

All about the UMC series of Haas

The Haas UMC series is one of the most popular CNC machine series of Haas.

These vertical machining centers from Haas have helped the brand attract many more customers in the CNC machining market.

Haas, as a brand, is well known for making CNC machines that are both affordable and reliable. The UMC series adds to this reputation by bringing precision machining to the forefront.

So, if you’re a machinist looking to buy vertical machining centers for your machining shop or just a CNC enthusiast, here’s a detailed article about the Haas UMC series that will help you understand everything about it.