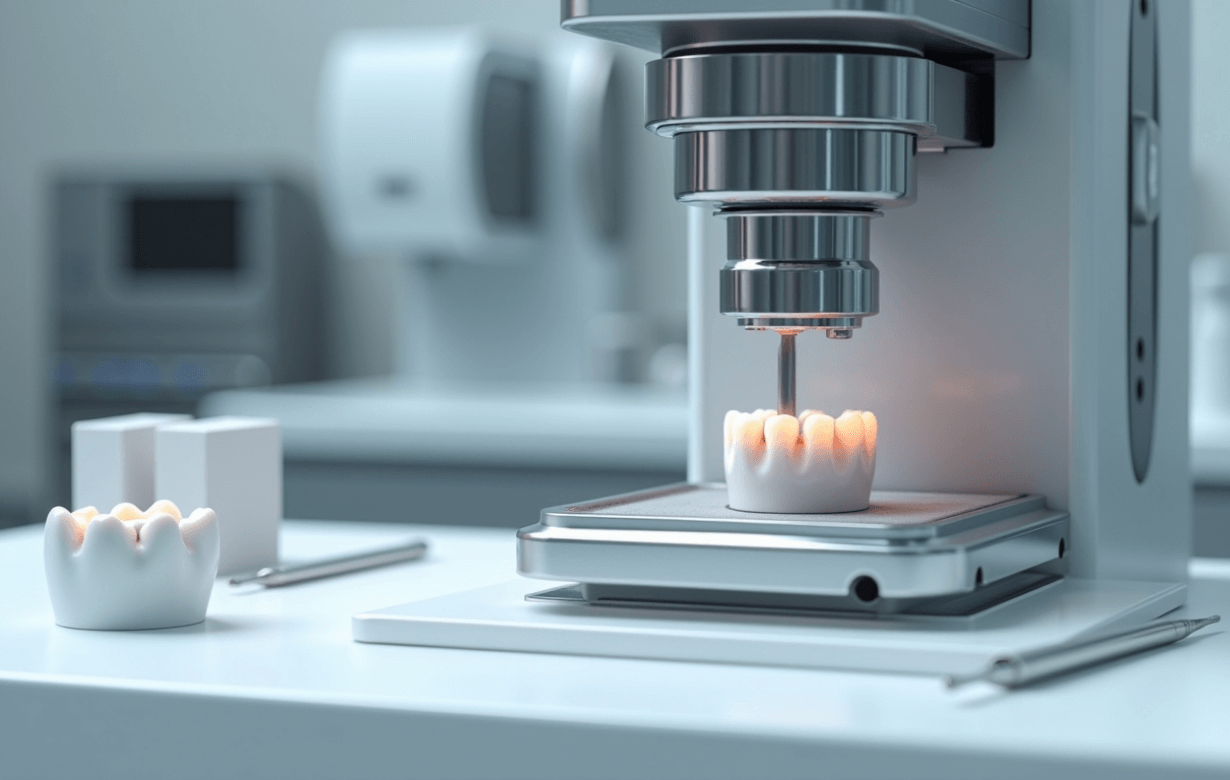

CNC machines for Dental Crowns

Dental clowns are small, miniature objects that require precise and high-tolerance machining capabilities to achieve the best shape, size, and fit inside a patient’s mouth. That level of accuracy is very tough to achieve if done with manual machining, so the right option for machining these products is CNC machines. However, as CNC machines come in various shapes with different specifications, which one is needed for manufacturing dental crowns? The answer is 5-axis CNC milling machines, as they are one of the finest options of machining out there that can help in making dental crowns. So, let’s dive deep into finding out how CNC milling machines can help in making the best dental crowns.