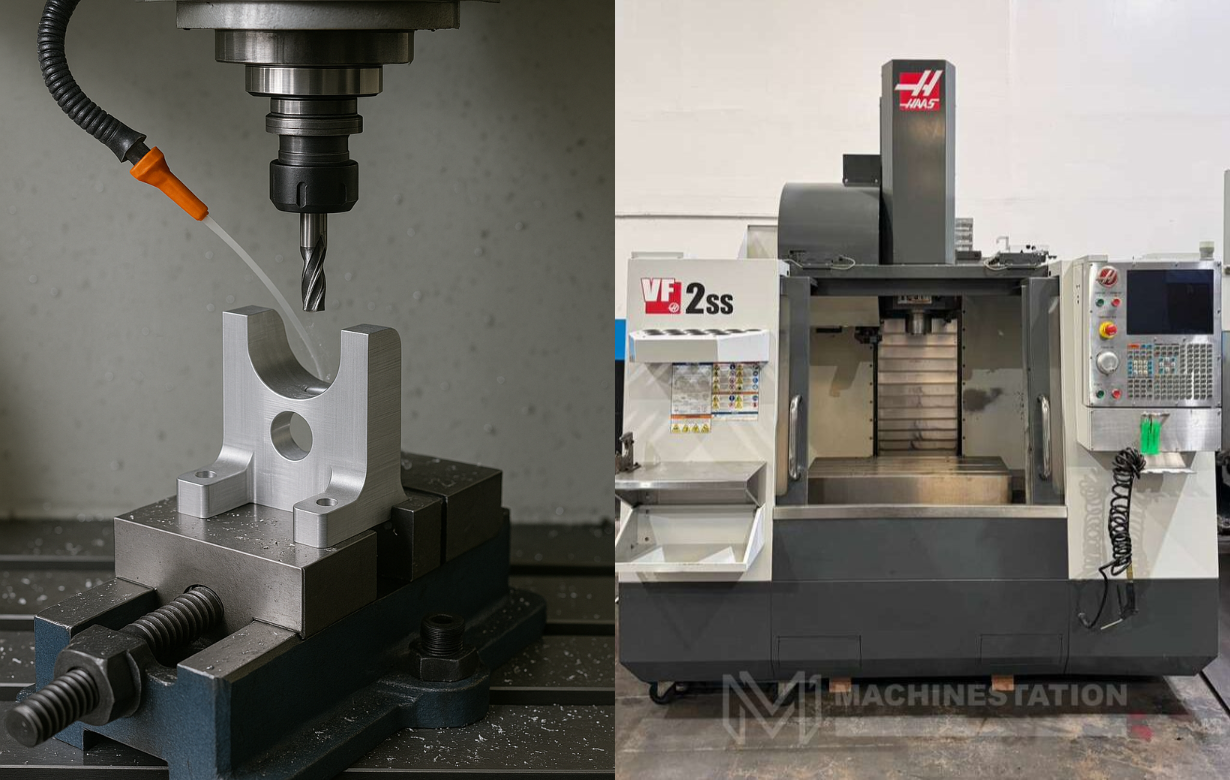

Step-by-Step Guide to CNC Machining for Beginners

CNC machining has revolutionized the whole world of manufacturing due to its automation features that have helped machining shops to get a thing done at a minimal cost and with less human effort compared to traditional machining. But learning how to run a CNC machine is a tough job, as it has different critical features that you need to be very well aware of.

From coding to aligning the axes of the machine, you need to focus on several things to ensure proper CNC machining. So, in this blog, we will be discussing the top things that one needs to know like what does a CNC machine do and how to operate a CNC machine for a beginner who has just started exploring CNC machines.