Top CNC Machine Buying Mistakes to Avoid:

Here are some of the major points of what to know before buying a used CNC machine or a new one:

1. Not Defining Your Production Needs Clearly:

One of the major mistakes that most people make when going to buy a CNC machine is making the purchase decision without understanding their own machining needs properly. Buyers often get carried away by brand names and high end features, without realizing that they might not need such costly machines.

Before your purchase, ask yourself:

- What materials will you be machining?

- What part tolerances are required?

- What is your expected production volume?

- Do you need a 3-axis, 4-axis, or 5-axis machine?

Tip: Make sure you write down your requirements and then discuss them with the team of the platform from which you are going to buy the machine. You can discuss that with our team in MachineStation, and they will help you get the right used CNC machine for your machining needs. Our team will guide you through your question of what CNC machine should I buy.

2. Ignoring Machine Compatibility with Facility:

The next CNC machine buying mistake that people often make when going to buy a CNC machine is that they overlook the physical and utility needs of the CNC machine they are planning to buy. Even the best of machines won’t perform well if your workshop is not equipped to handle them.

Common oversights include:

- Not checking the power requirement of the CNC machine.

- Ignoring the floor space and weight capacity of the machining shop.

- Overlooking the coolant and air supply needs.

- Forgetting about noise and ventilation considerations.

Consequences:

- Machines won’t fit through the doors or in the intended space.

- Inadequate power supply or air pressure.

- Costly modifications of the shop and delays in the start of production.

Knowing your shop’s compatibility will help a lot with which CNC machine to buy.

3. Buying Without Understanding the Machine’s Compatibilities:

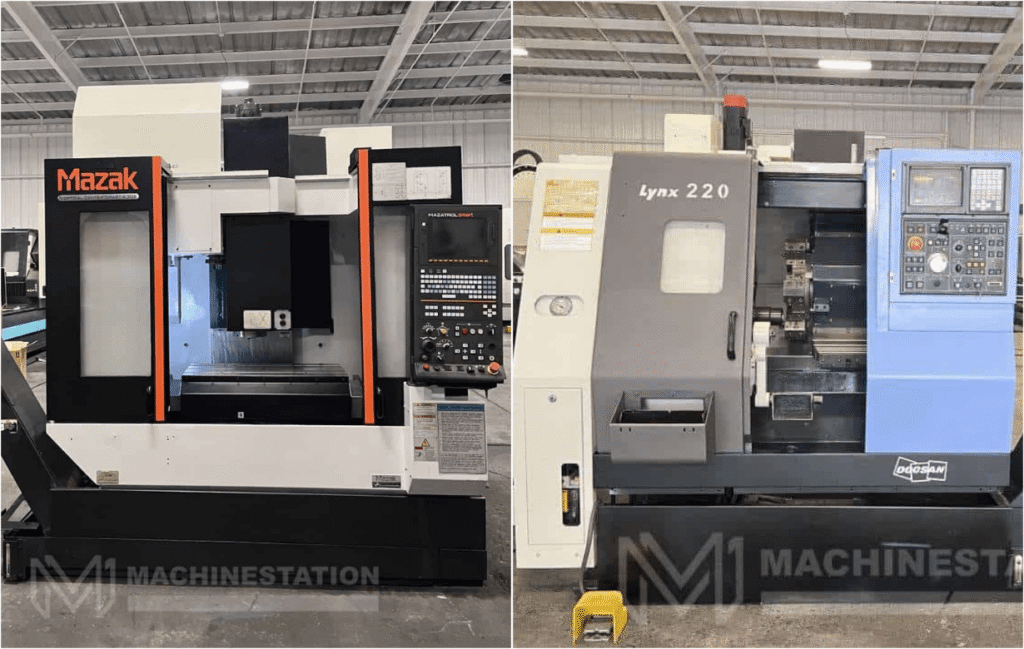

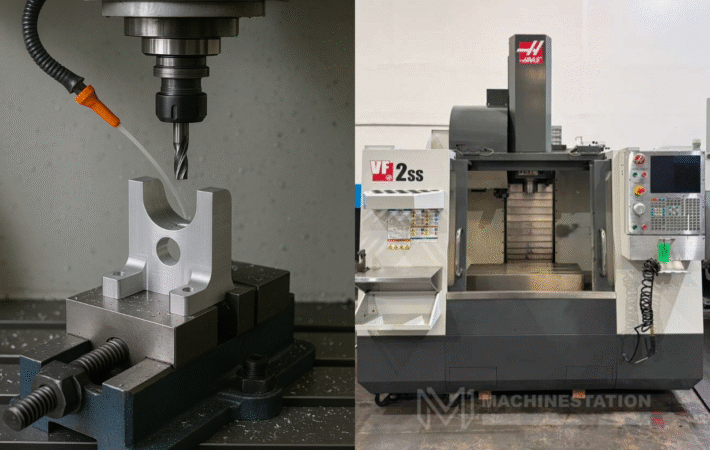

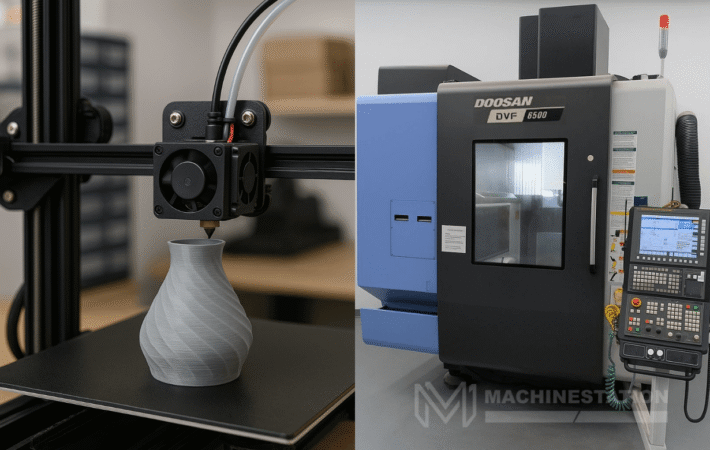

Different CNC machines serve different purposes. They are optimized for different materials, different volumes or production, and different shapes of products, so you will have to be well aware of that before making the purchase.

For Example:

- A CNC Mill is ideal for working with heavy materials and complex designs.

- A CNC Lathe is used for making cylindrical parts.

- A CNC Router is ideal for cutting softer materials like wood and plastics.

- A multi axis machine can be used for cutting complex parts in just one setup.

Tip: Understand different types of CNC machines, and then buy the one that fits your machining needs.

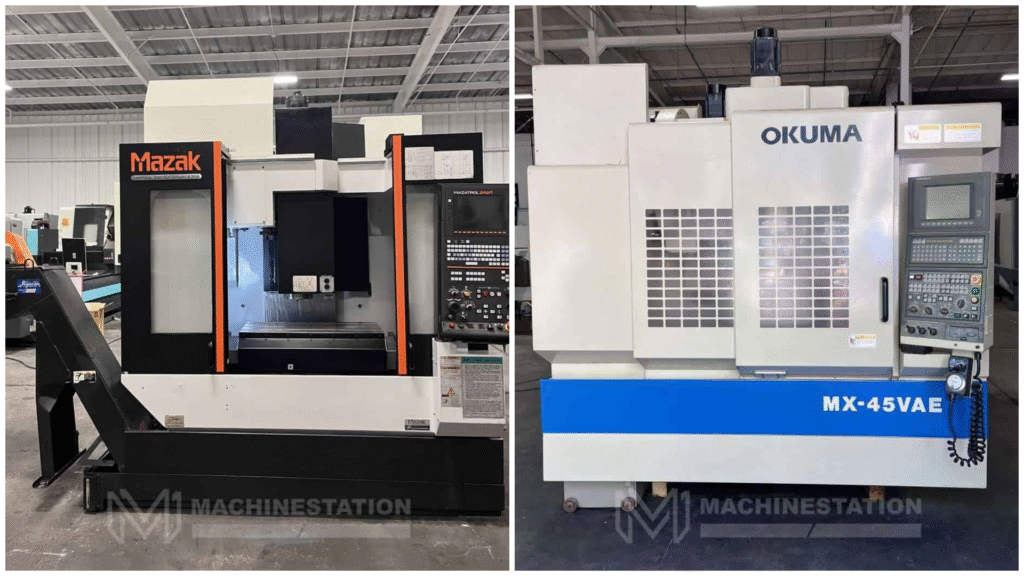

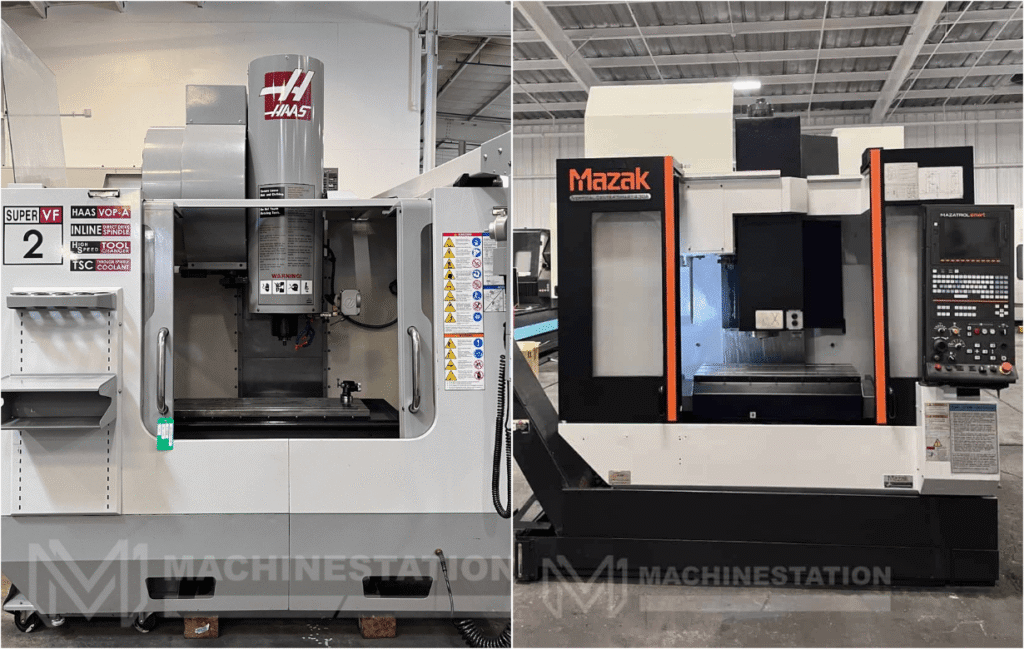

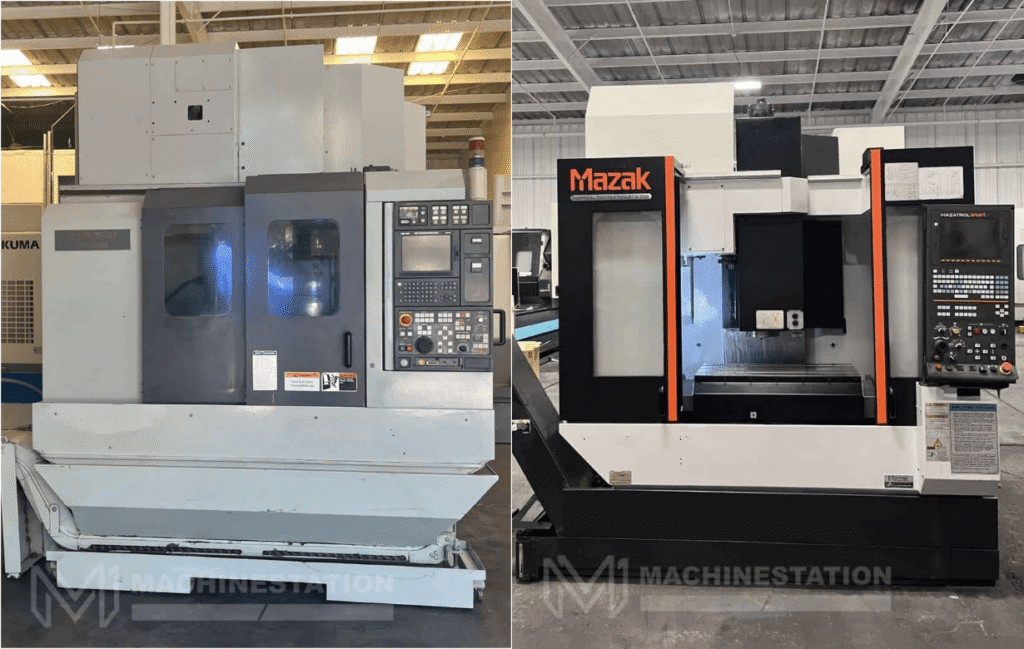

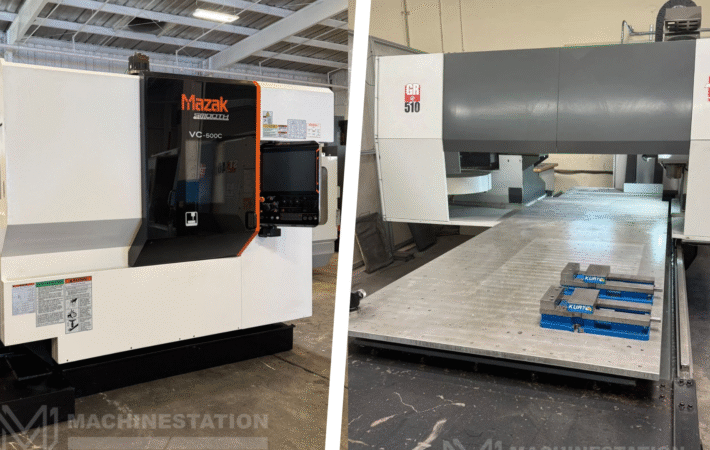

4. Buying Without Researching Brand and Seller:

Not every CNC machine is equal, and not every CNC machine seller is equal. So it is always very important to be aware of the brand you are buying and the platform you are buying it from. Different brands are popular for different things, like Haas CNC machines for affordability, DMG Mori CNC machines for advanced tech, and Okuma CNC machines for longevity.

What to look for?

- Reputation and review of other users.

- Availability of spare parts and service networks.

- The experience of the seller.

Tip: Always buy from experienced sellers like MachineStation, as they can make the whole delivery process much more seamless. To understand our experience in the industry, check our previously sold machine collection, and that will help you get the answer to your question about where to buy used CNC machines.

5. Understanding the Importance of Training:

One of the biggest CNC machine buying mistakes one makes is buying a high end model that their machinists are not trained for.

Sellers often try to upsell high end machines, but you must make the purchase call after checking the skill levels of their machinists. Assuming the operators will “figure it out” leads to errors in machining and inefficiency.

Tip: Either buy CNC machines whose features match the skill levels of the operators of your shop or get your operators trained before making the purchase.

6. Ignoring Software Compatibility:

CNC machining is not only about the hardware, like the axes and spindle, but also about the software of the machine. Software is the bridge between the design and the finished product. Failing to understand software compatibility can lead to expensive upgrades.

Ask yourself:

- Is the machine compatible with your existing CAD/CAM software?

- Does it use a common G-code language?

- Are post processors available for your specific machine control?

Tip: Ensure seamless integration between your design and machining software before finalizing your purchase. This prevents rework, translation errors, and lost productivity.

7. Overlooking Automation and Connectivity Features:

Last but not least, CNC machine buying mistakes are overlooking automation capabilities. Automation has become very important in the modern manufacturing scenario, or you will not be able to compete with other manufacturers with production volume.

So, when you are buying a CNC machine, new or old, ask the shop what automation features are already available in the machine, like ATC, and if there is potential for more automation upgrades for the machine, that’s more applicable when buying a used machine of an old model.

Conclusion:

We have listed some common CNC machine buying mistakes that people make when buying a CNC machine, no matter if it’s old or new. But one summarized tip that we want to give is to read and learn everything before you go to make the purchase, especially if this is your first CNC machine purchase, which will help you make a sane decision of which CNC machine to buy.

FAQs:

1. How can I calculate the total cost of owning a CNC machine?

Ans: Add up not just the machine’s purchase price, but also costs for installation, tooling, CAM software, training, maintenance, and energy consumption over several years. This gives a more realistic picture of your long-term investment.

2. Is brand reputation important when buying a CNC machine?

Ans: Yes. Reputable brands like Haas, Mazak, DMG Mori, Okuma, and Doosan offer better durability, service support, and resale value. Unknown brands may appear cheaper, but they can lead to problems with parts availability and maintenance.

3. Why is operator training crucial after purchasing a CNC machine?

Ans: Even skilled machinists need to understand the control system, software, and maintenance of a new machine. Proper training reduces errors, improves part accuracy, and ensures safe and efficient operation.

In This Post

- Not Defining Your Production Needs Clearly

- Ignoring Machine Compatibility with Facility

- Buying Without Understanding the Machine’s Compatibilities

- Buying Without Researching Brand and Seller

- Understanding the Importance of Training

- Machine Rigidity and Construction:

- Ignoring Software Compatibility

- Overlooking Automation and Connectivity Features

- Conclusions:

- FAQs