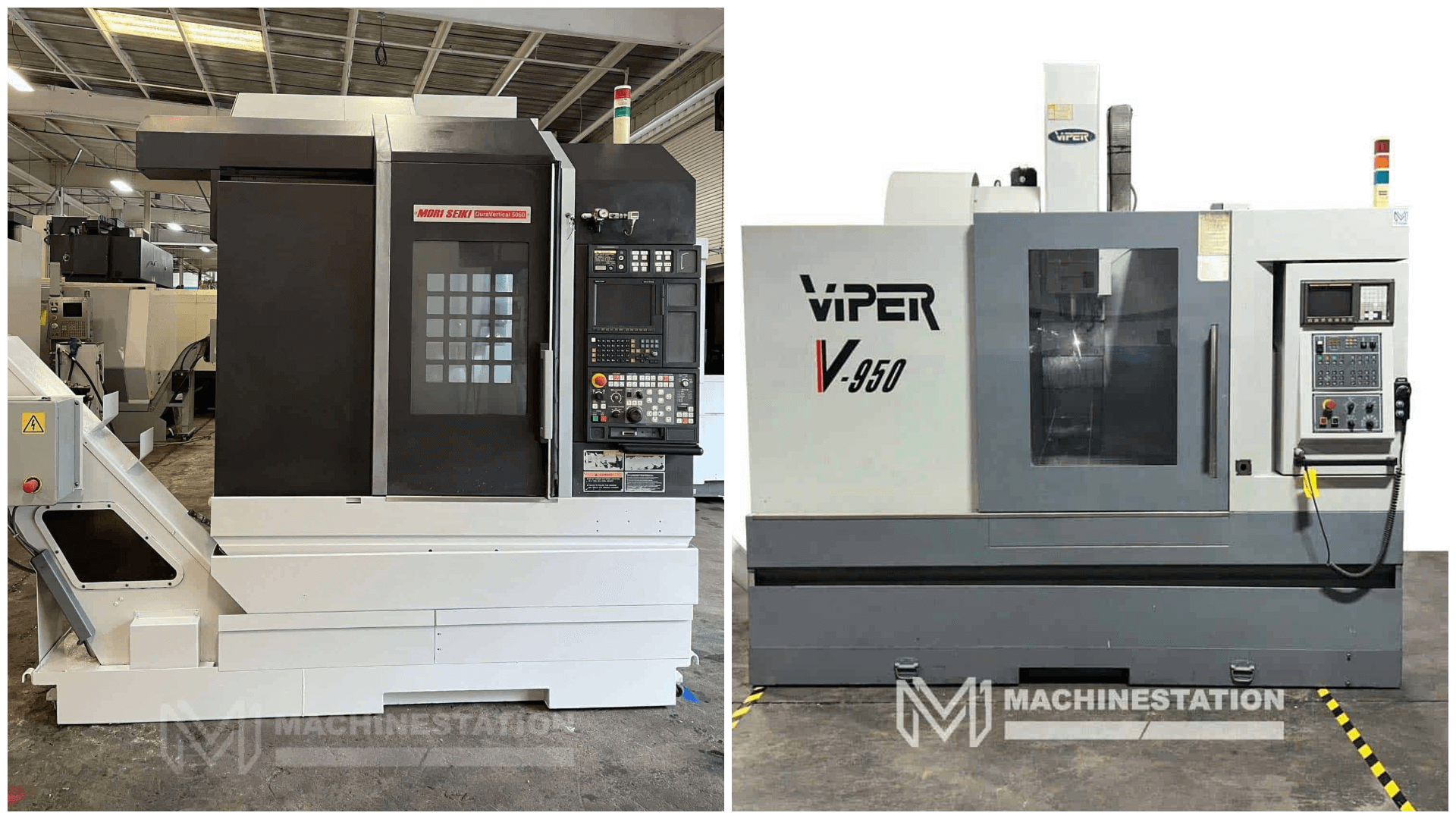

DMG Mori vs Mighty Viper – Which CNC brand is better?

CNC machines come in different styles, different mechanisms, and different brands. Not all are good for your business, but some of them are great for your business, especially when it comes to the CNC machine’s brand. While machines of some brands don’t work properly and last for very short periods, there are also some brands that have strengthened their brand names by making and supplying strong and robust CNC machines. They have continuously innovated their technologies and features, and always kept customer satisfaction at the top of their priority list. There are two brands that do all these things: DMG Mori and Mighty Viper. These two companies have been hugely successful in the CNC machine making business and are loved by several customers around the world. And in this blog, we will find out which one among these two can be the best for your business?