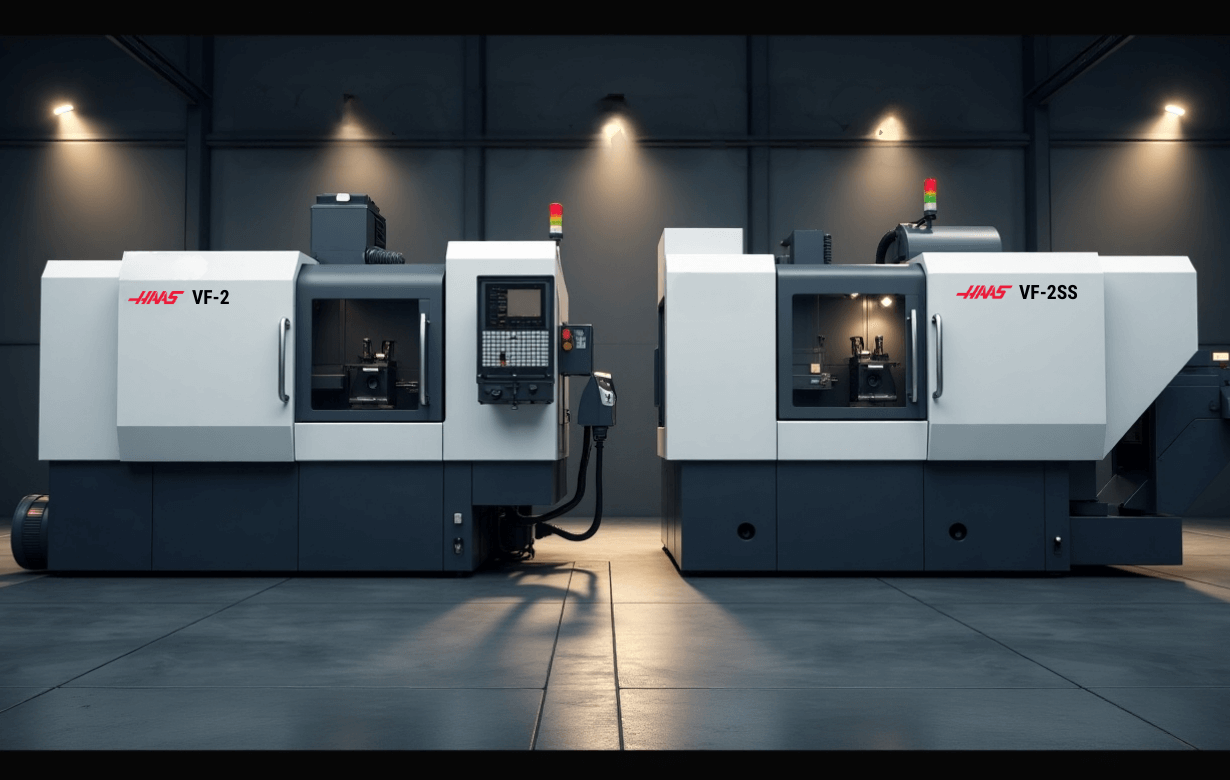

Haas VF-2 vs VF-2SS: Which Model Should You Choose?

Are you planning to buy a Haas CNC?

Or are you planning to buy a vertical machining center, CNC?

In case you’re trying to be a jack of both, then there is good news: there is a right machine series for you, which is the Haas VF series. The VF series features several CNC vertical machining centers that excel in performance. Among them, two of the most famous are the Haas VF2 and the Haas VF2SS.

So, which one should you choose among these two machines? In reality, there is no clear cut answer to these questions, as which one is better for you can totally be determined by which one satisfies your particular business requirements. So, let’s jump into finding out which CNC machine, among VF2 and VF2SS, is better for your machining business.