How do I change tools on a CNC machine?

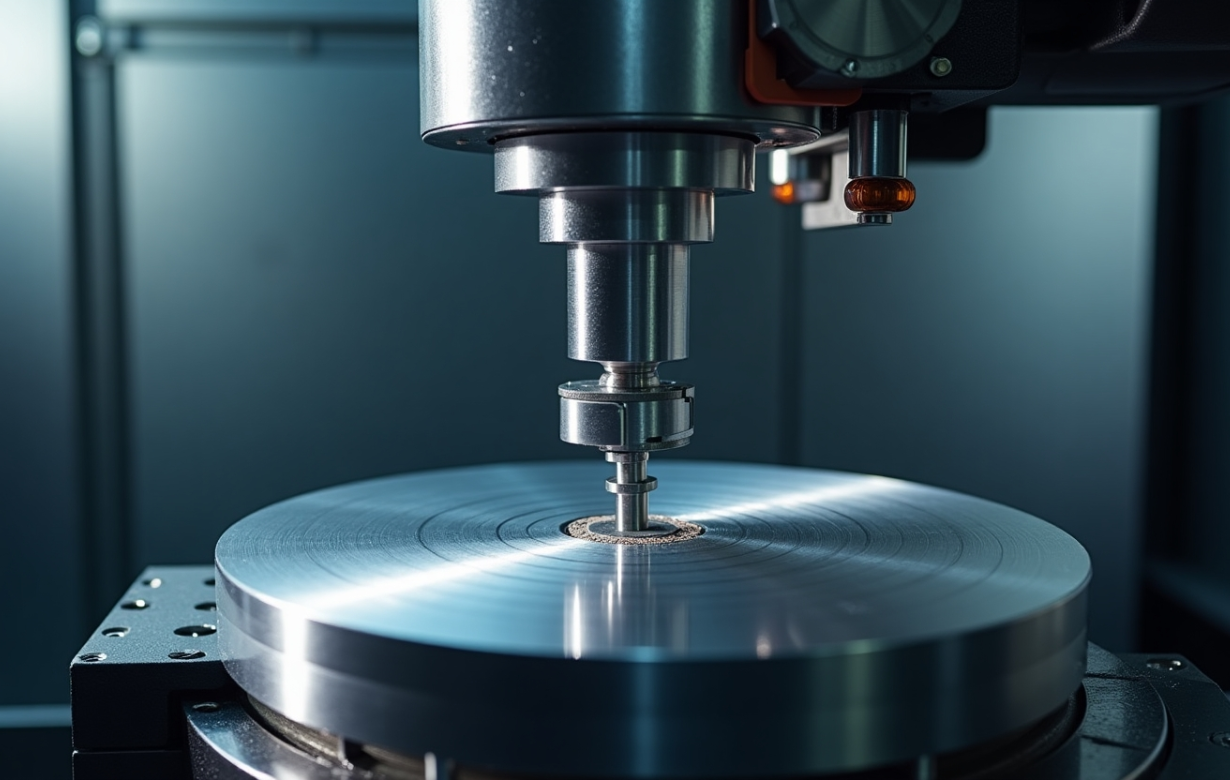

The main pillar for CNC machining is the cutting or milling tool working inside of it. One of the most important skills for any machinist is to know how to change the tools for the machining work. No matter if it is in a small home shop or a large industrial setup, knowing how to change the tool in the CNC machine is highly important. Though experienced machinists are able to do this easily, new ones often struggle a bit to understand the nuances of changing the tools on a CNC machine. So, if you are also someone struggling to understand the details of changing the tools on a CNC machine, then you have landed on the right page.