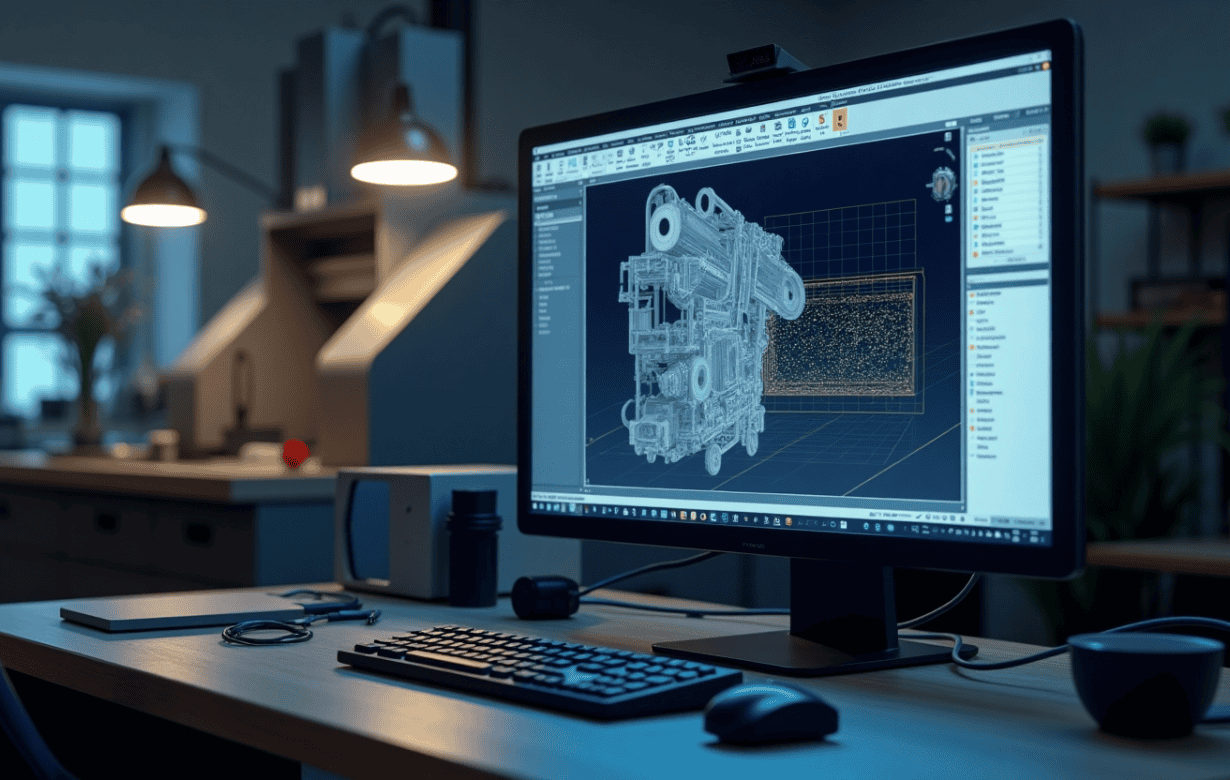

How do I convert a CAD file into G-code

CNC machines are used for developing different kinds of complex structural products of different materials like steel, aluminum, and wood. CAD or Computer Aided Design software helps you to create a digital prototype of the final product that you wish to create with the help of the CNC machining process. To help the CNC machine execute the necessary moves to make the desired product one will have to convert the CAD file into a G-Code, which is a program that instructs the CNC on how to move and in which direction to move to complete the machining process.