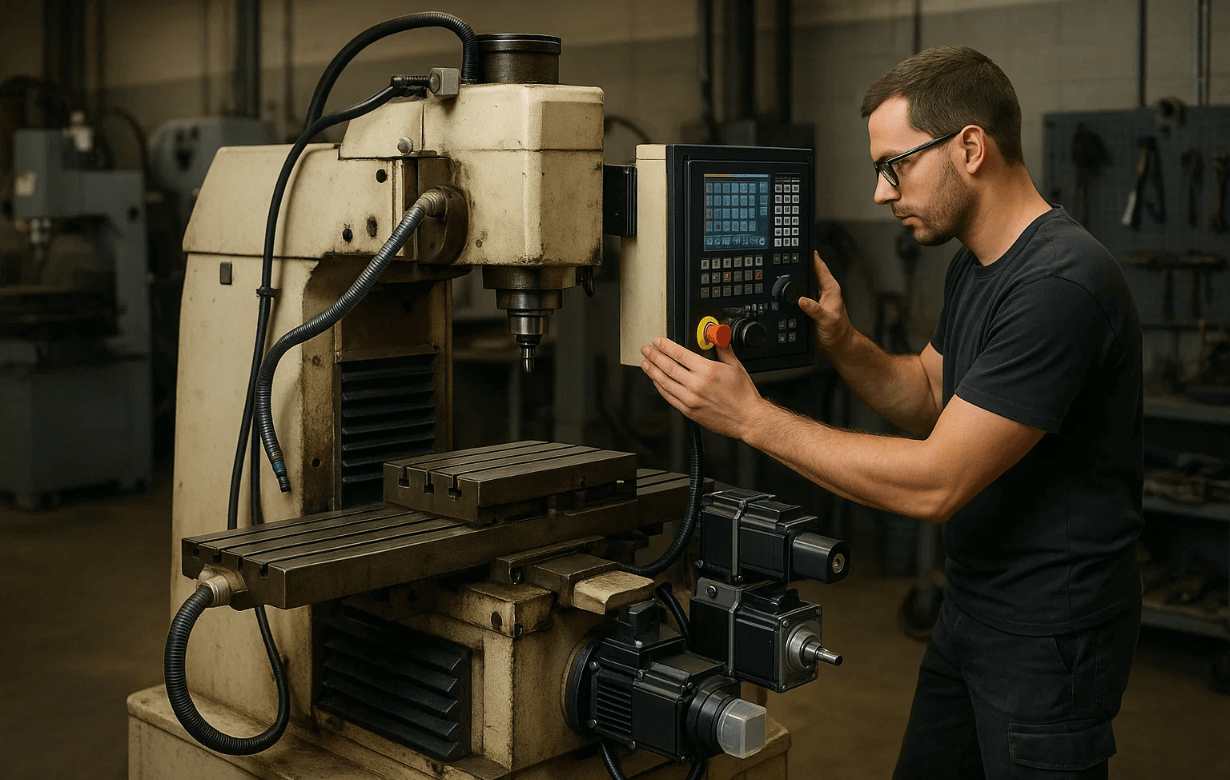

How to Upgrade Your Used CNC Machine for Better Performance?

When you buy a used CNC machine, you save a lot of upfront costs but you might have to spend some more money for upgrading to make it the same as new CNC machines and the total spending will be still less than new CNC machines. Some top quality upgrades can make the old and used CNC machines as good as the new advanced ones and give you a strategic gain for a better and faster machining process. Knowing how to approach the upgrade of the used CNC machine can help you with efficiency, precision, and productivity. In this blog, we will discuss how you can find the best upgrades needed for your CNC machine.