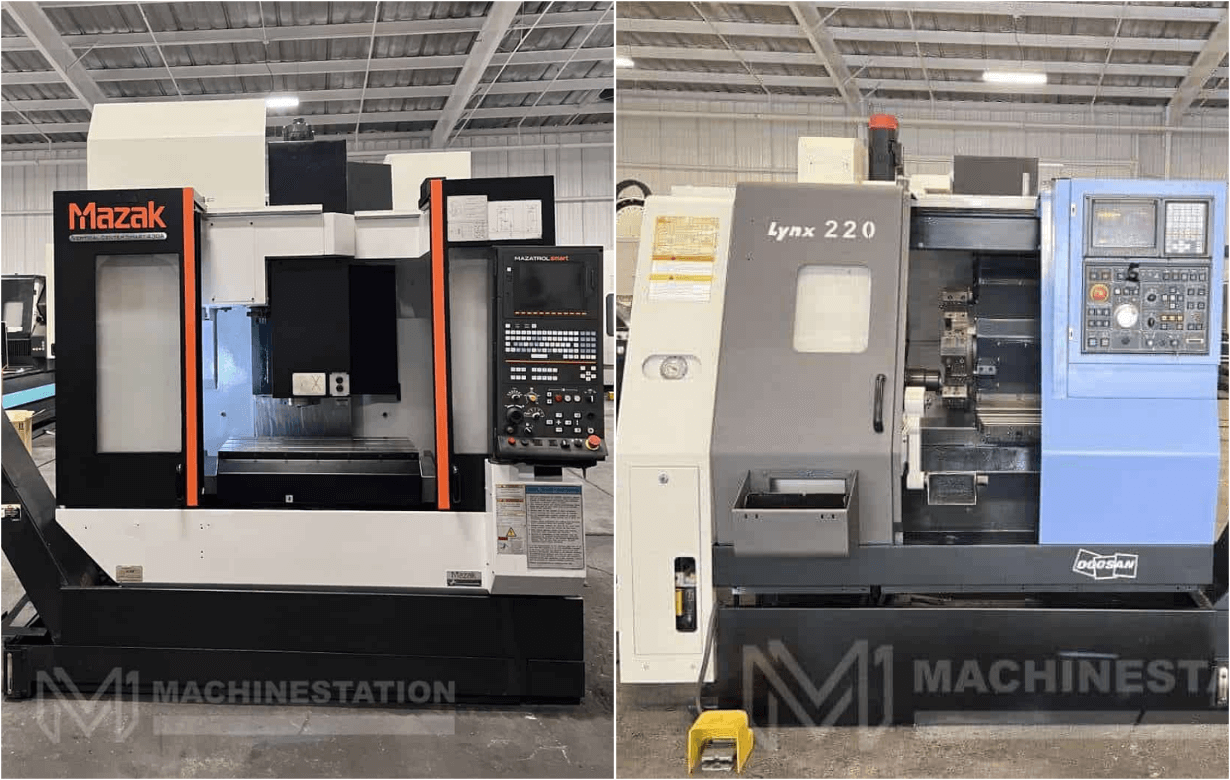

Mazak Vs Doosan – Which CNC brand is better?

There are several CNC brands available around the world that supply different styles of CNC machines with different advanced features but most of them lack one thing – trust of customers. But there are some brands too which have owned the trust of their customers by supplying top notch CNC machines to their customers over the years while innovating for the best features with more passing time. Two such brands are Doosan and Mazak, which need no introduction because everyone who is interested in machining knows them. But which one among them is better? Let’s find that out.