The Best Accessories & Add-ons to Improve a Used CNC Machine

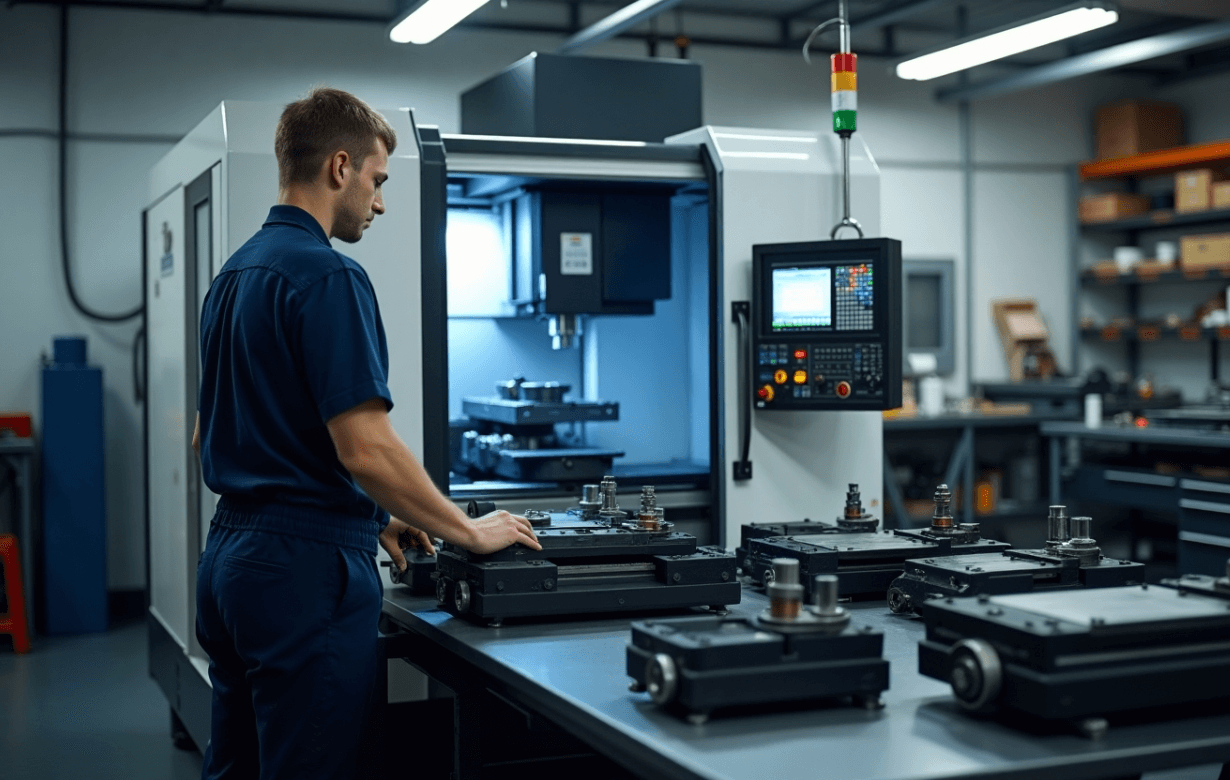

A well-functioning CNC machine can become your biggest strategic advantage over your competitors if you are in the manufacturing business. A well performing CNC machine can help you produce more parts efficiently and accurately. When you purchase a new advanced CNC machine, you receive assurance from the brand about its performance; however, the machines are often too expensive. So what to do? The answer is you can get that same top notch level of performance using used CNC machines. Even if they have some weaknesses you can just get some new accessories or add-ons to improve that machine easily at a lower cost. But what accessories do you need? Or which one will be the best? If you have any one of these questions in your mind then continue reading till the end and you will get the solution.