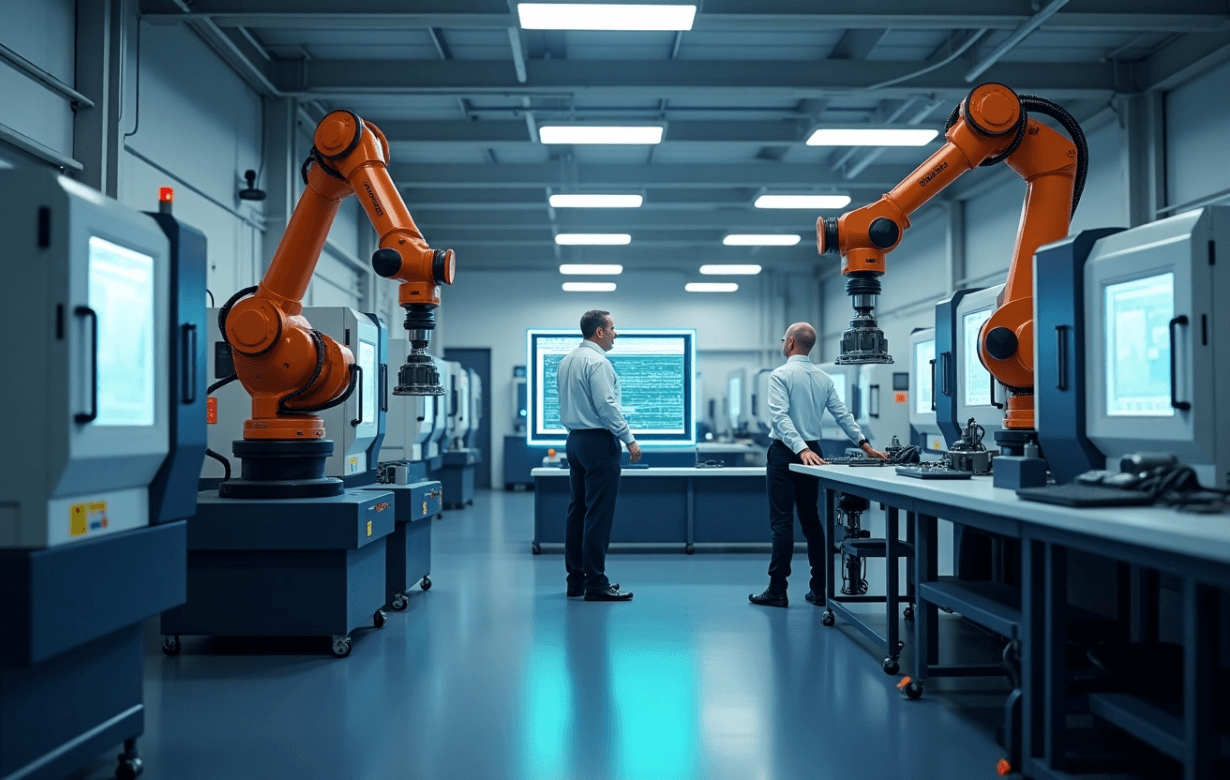

The Role of Automation in CNC Machining

Automation of different tasks is the new normal, from web development to driving, everything is getting automated. AI is taking over a lot of manual work, and the same trend is visible in CNC machining. The best brands of CNC machines are integrating automation with their machines at the highest speed ever, and users are also looking for machines that will help them reduce manual labor and get the machining job done in a more seamless manner. But how exactly is automation changing the CNC machining world and what does the future look like? Let’s try to find that out in this blog.