What are the benefits of Multifunction CNC Machines?

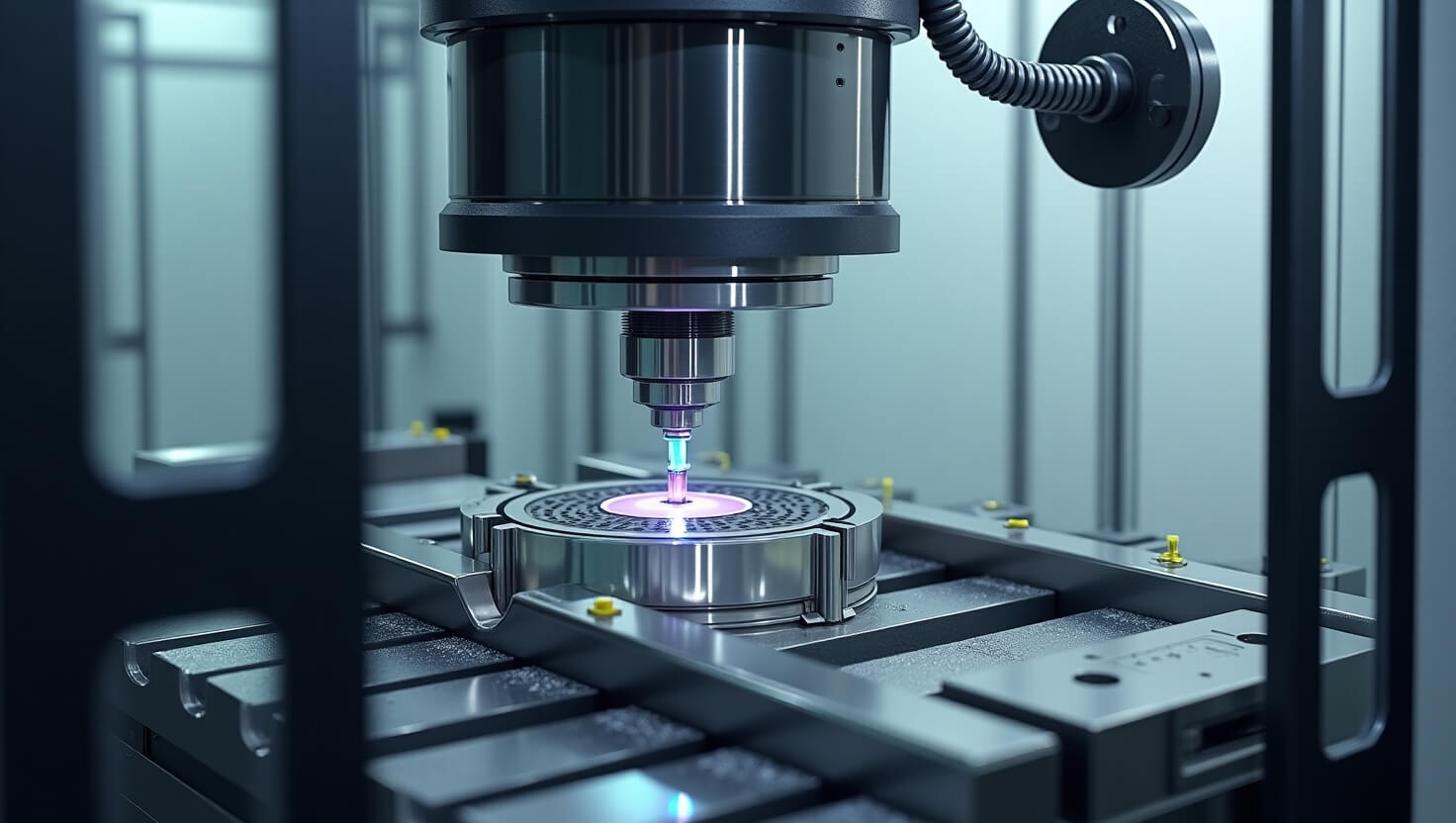

CNC machines have come a long way from being human-controlled milling machines born out of a collaboration between John Parsons and Frank L. Stulen to being totally automated, multi-functional CNC machines that can perform all kinds of machining jobs in just one setup. Modern machines are more advanced, efficient, accurate, and have tighter tolerances, but they are also somewhat costly. The price tag gets justified by the benefits the multifunction CNC machines bring to their customers. If you are also a CNC machine shop owner and planning to get a new machine for your shop, then buying a multifunction CNC can be your best choice. Want to know why? Let’s get that discovered.