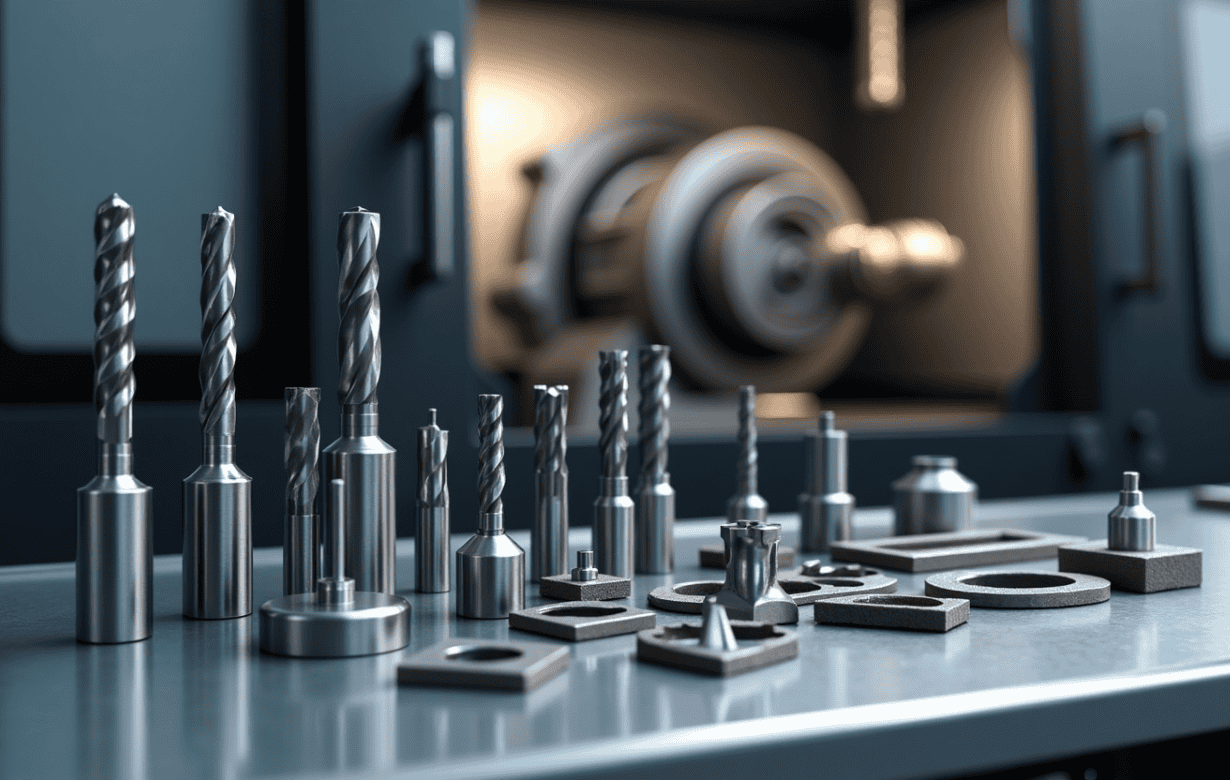

What cutting tools are employed in CNC machining?

CNC machines are now the backbone of the manufacturing industry, helping to shape various raw materials into usable parts that can be utilized by other businesses. At the heart of these CNC machine technologies are the cutting tools that are used to change the shape of the raw workpiece into a desired shape, and there can be different types of cutting that a CNC machine can use to do that job. The selection process of which tool is needed can be made using various metrics like the materials that are to be machined or the work that needs to be done like milling or drilling. If you are also curious about which cutting tools are often used by CNC machines and for what purpose, then you have landed on the best page and now let’s continue till the end.