Why is an Engine Lathe?

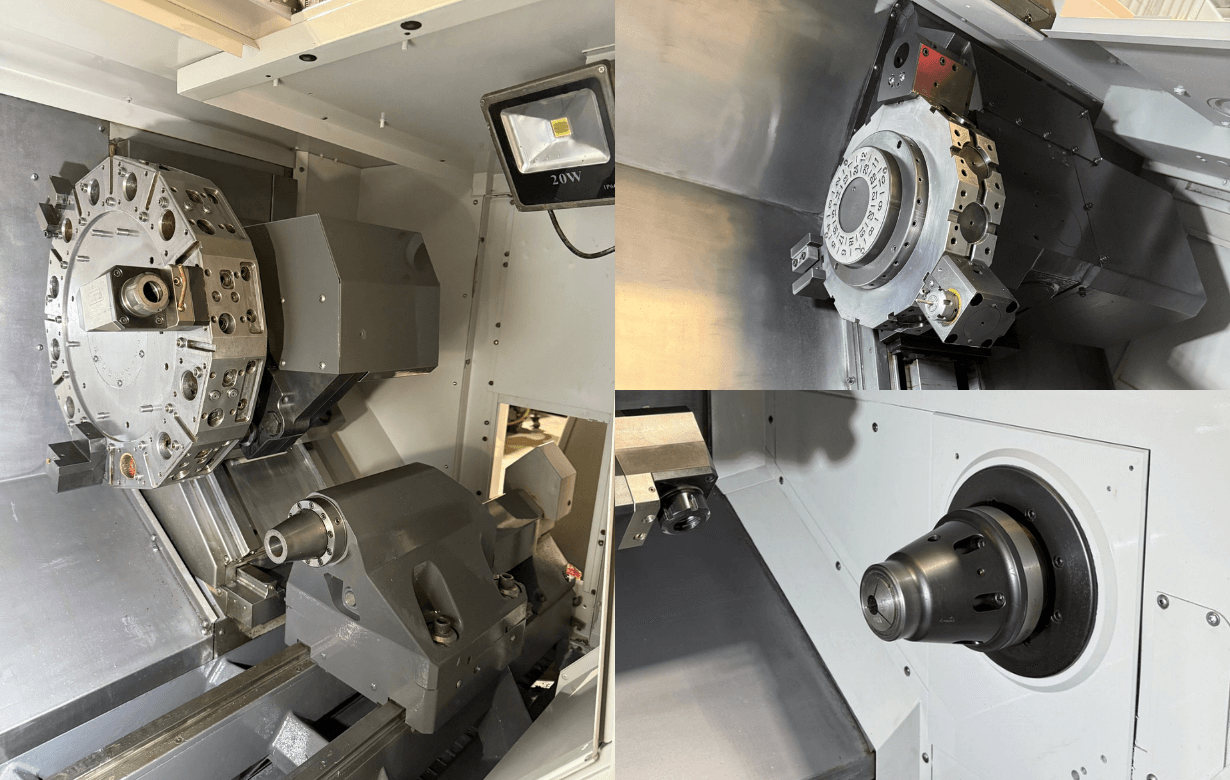

CNC machines have different variations, and each of those types is used for machining different materials and making different products of different shapes. An engine lathe is another type of CNC machine that is widely used for metalworking all around the world. They are called “engine” lathes because their previous versions were powered by steam engines. These machines are helpful for different kinds of machining work, so if you want to know about these lathes in detail, then this is the right place for you.

Let’s dive deep into finding out the details of an engine lathe.