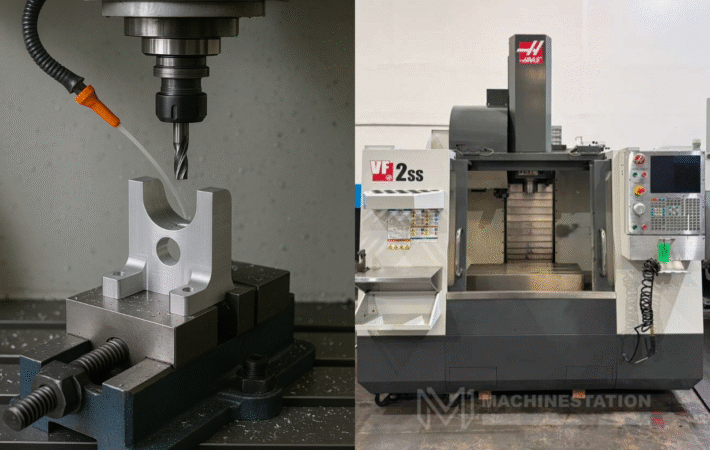

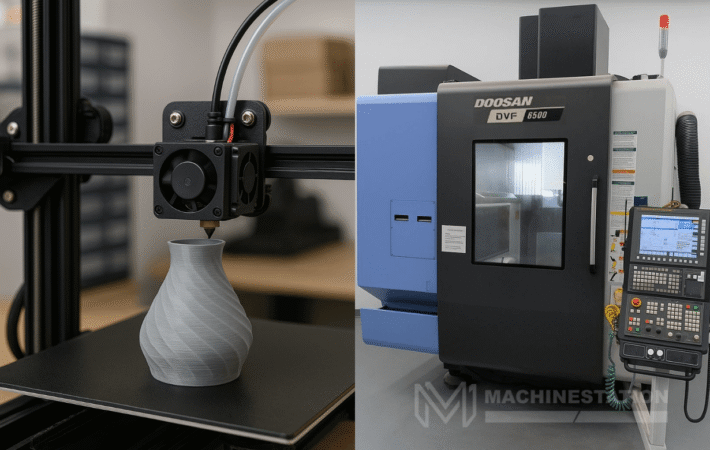

What is CNC Machining, and How Does It Work?

Computer Numerical Control (CNC) machining has been a complete game changer in modern manufacturing. These machines are useful for any machining in any industry you can think of; a lot of parts for industries like aerospace, automotive, medical instruments, and jewelry are made with the help of CNC machining. These machines have automated the heavy, laborious work of manufacturing, and that also helps in the accurate and precise machining of different products. This whole process of manufacturing in these CNC machines is done with the help of pre programmed computer software commands. So, now if you want to understand CNC machining and how it works, then let’s continue with us till the end.