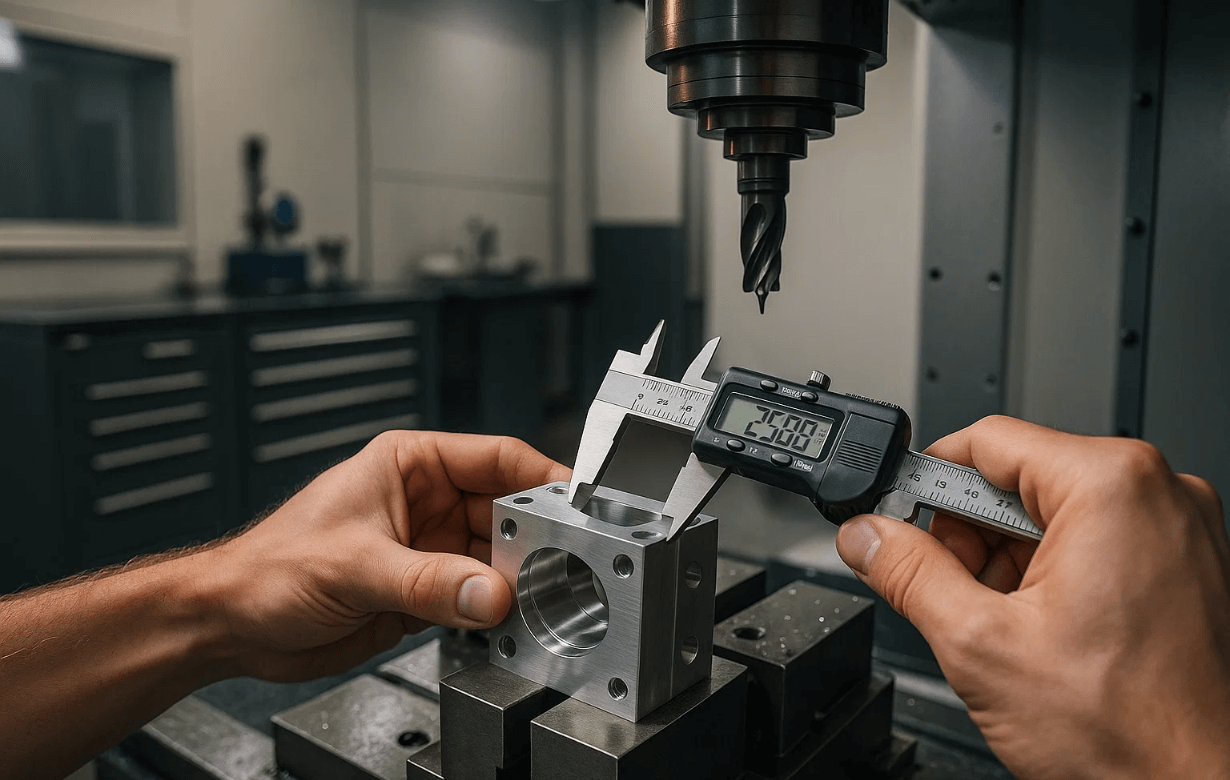

What is machining tolerance, and how is it achieved?

Machining is a tough job that needs to be done by maintaining accuracy and precision and for that you will have to keep in mind different metrics, and follow them religiously. There can be different metrics that one needs to follow during machining depending on the material they are working on, or depending upon the type of machining they are doing. But one factor they need to be aware of irrespective of both circumstances is machining tolerance. One needs to achieve the right machining tolerance to have the perfect product created through the machining process.

But if you are worried about what machining tolerance is and how you can achieve it, then no need to worry anymore because you have landed on the best page that will help you to get a deep clarity about machine tolerance.