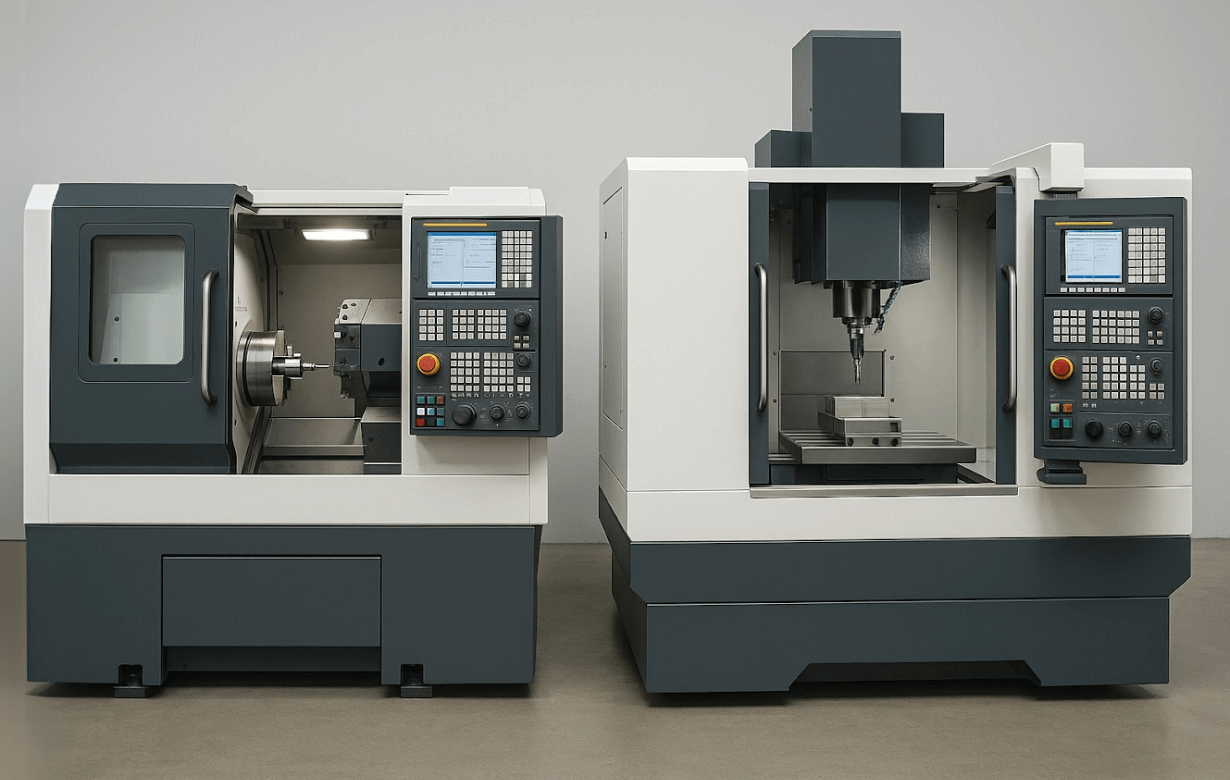

What is the difference between a CNC Mill and a CNC Lathe?

CNC machines have revolutionized the entire manufacturing process worldwide. The precise work of making a tool perfectly for commercial use can now be done by just some coded commands without the need for any hard manual labor. The CNC machines can now work on machining of different kinds of materials and make different shapes, and parts with different styles of machines. CNC mills and CNC lathes are two different types of machines that serve different purposes helping in making unique products. But most people are not very clear about what these machines are used for. So, if you are also one of them and want to know the difference between a CNC mill and a CNC lathe, then read this blog and all your doubts will be cleared.