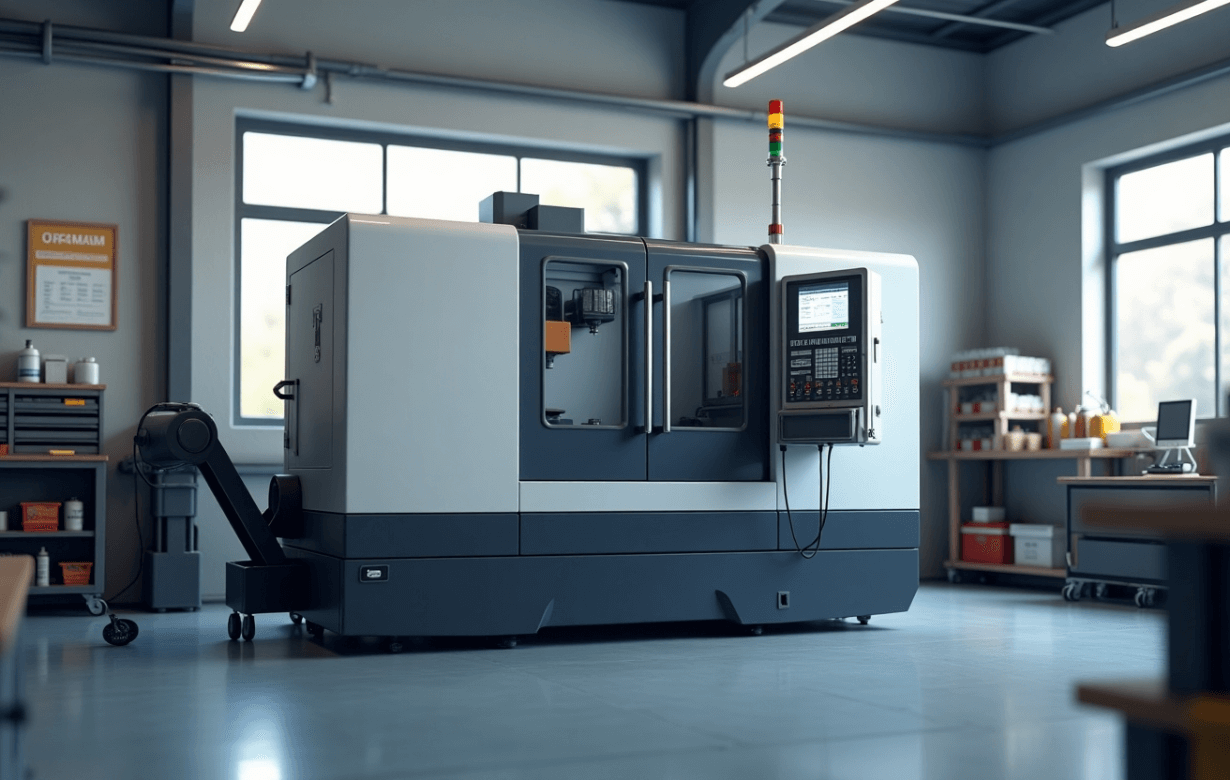

What is the life expectancy of a CNC machine?

When someone buys a CNC machine, one thing that might trouble their mind the most is how long the machine is going to last. To be honest, there is no direct answer to this question. The life expectancy of a CNC machine is determined by several factors, and you cannot control them all. But you can try to enhance the life of your CNC machine by following some steps, and we will discuss that here. Not only that, but what factors influence your machine’s life and how you can do predictive maintenance for a better lifespan of the machine will be discussed in this blog. So, let’s dive deep to know all the details about the life expectancy of a CNC machine.